Operating Manual

English

13

Connect the black jump lead first

to the negative terminal (–) of the

donor battery. Connect the other

clip to the frame of the engine

block of the tractor with the flat

battery (as far away from the

battery as possible).

Note

If the donor battery is installed in a

vehicle, this vehicle must not be

started during the jump starting

process.

Start the tractor with the flat

battery and actuate the parking

brake.

Disconnect the jump leads in

reverse sequence.

Tyre pressure

Warning

Never exceed the maximum

permitted tyre pressure (see tyre

wall). When pumping up the tyres,

do not stand in front of or over the

tyre.

Excessive tyre pressure reduces

the service life of the tyres. Always

check the tyre pressure before

driving.

After 5 operating hours

First engine oil change. See

engine manual for subsequent

intervals.

Use the oil channel or (optional)

quick oil drain (Fig. 16).

After 10 operating hours

Lubricate all rotating and bearing

points of the accelerator pedal

and brake pedal with several

drops of light oil.

Clean battery poles and

terminals.

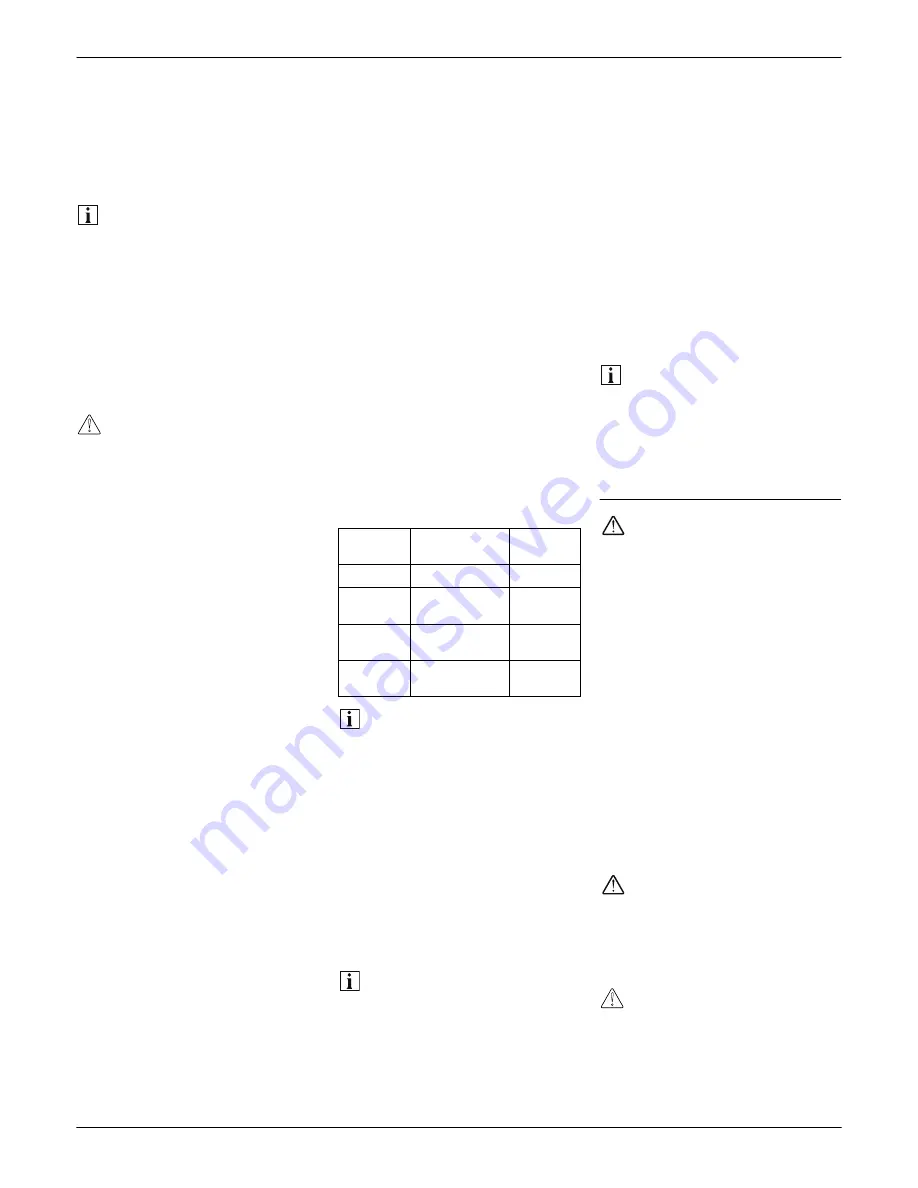

Every 25 operating hours

Lubricate all blade shafts,

tensioning pulleys and

tensioning pulley holders via the

grease nipples using grease type

251H EP. Have this work carried

out by a service centre.

Lubricate the wheel bearings and

front wheel axes with 251H EP

type grease applied to their

respective grease nipples.

Remove grass and dirt around

the blade shafts beneath the

covers. Have this work carried

out by a service centre.

Lubricate the steering with

grease Type 251H EP via the

grease nipples on the steering

support. Have this work carried

out by a service centre.

Every 50 operating hours

Have dirt and grass remnants

removed from the drive gear by

a repair shop.

If required

Charge the battery

If you are not using the unit for

a prolonged period, it is recommen-

ded to take the battery out of the

unit and charge it before storage,

as well as every 2 months during

storage, and before starting up the

unit again.

Check the battery’s charged state

with a voltmeter. When the charged

state is less than 12.6 V (DC)

recharge the battery (max 12 V

at 6 A) with a battery charger in

accordance with the table.

Note

Follow the instructions in the

operating manual for your battery

charger.

Replacing fuses

Replace defective fuses only with

fuses of the same amperage.

Hydraulic expansion vessel

Fig. 17

Is used as an expansion vessel for

the hydraulic fluid during operation.

Maintenance and inspection only

by a specialist company during

annual maintenance.

Notes

– Do not check until the hydraulic

oil has completely cooled down.

– The oil level should be at least

between the base of the tank and

the mark (1).

Once per season

Lubricate all rotating and bearing

points (operating lever, height

adjustment of the cutter deck ...)

with several drops of light oil.

Clean the spark plug and check

the gap between the electrodes

or replace the plug. See engine

handbook.

The rear axles must be lubricated

with a special-purpose (water-

repellent) grease at a specialised

garage.

Have the cutting blade

sharpened or replaced in

a specialist workshop.

Note

Regularly check (when visiting your

workshop) the condition of the

mower deck V-belt.

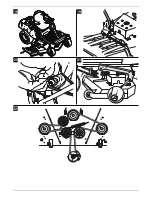

Removing/Installing and

adjusting cutter deck

Danger

Injury hazard if engine is started

inadvertently

Protect yourself against injury.

Before carrying out any work on the

mower

– park the appliance on a level

surface,

– switch off the engine,

– withdraw the ignition key,

– switch off PTO,

– lock the parking brake.

– wait until all moving parts have

come to rest and the engine has

fully cooled,

– remove the spark plug connector

on the engine in order to prevent

the engine from accidentally

being started.

Danger

Injury hazard due to sharp cutting

blade.

Wear protective gloves.

Disassembly

Warning

The hanger/lifting mechanism is

spring-loaded and may spring

upwards as soon as the cutterdeck

is disconnected from the lifting

mechanism – work cautiously.

Voltmeter Battery

charging state

Charging

time

12.7 volts

100 %

–

12.4 volts

75 %

approx.

90 min.

12.2 volts

50 %

approx.

180 min.

12.0 volts

25 %

approx.

280 min.