SITE PREPARATION AND INSTALLATION

3 - 3

Electrical Power Considerations

The MP6000 may be powered from two different sources:

•

POS Equipment

•

IBM register with powered Port 9B interface (using p/n CBA-M51-S16PAR accessory cable)

•

NCR POS with powered RS-232 interface (using p/n CBA-R55-S16PAR accessory cable)

•

Any register with powered USB interface - 12V only (using p/n CBA-U52-S16PAR accessory cable)

•

AC/DC power cube (using p/n PWRS-140000-148R) with IEC style modular line cord.

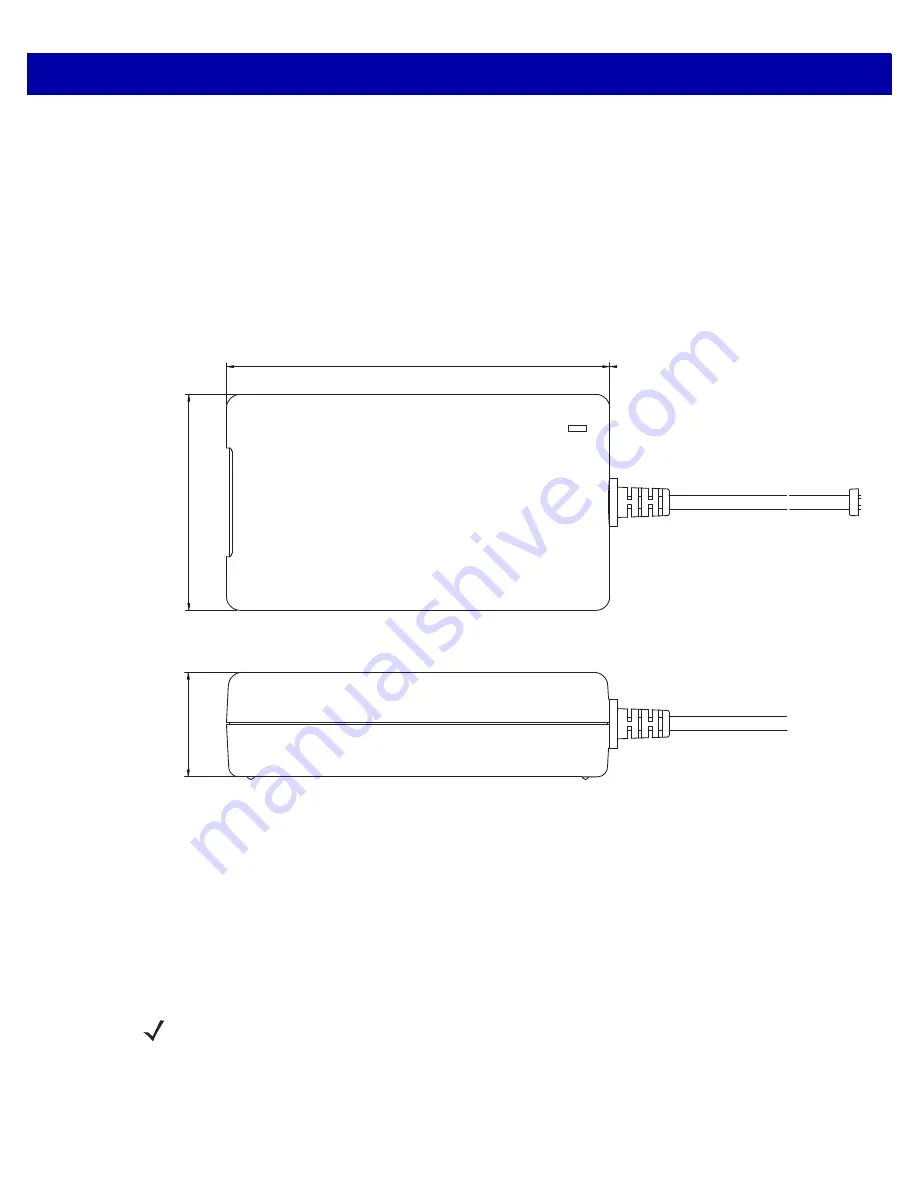

Figure 3-2

Power Supply

If using the AC/DC accessory power supply, a 115V/230V outlet must be available in the checkstand near the

scanner.

Grounding

All POS equipment should be properly grounded, and only a three prong IEC style line cord should be used

with the AC/DC accessory power supply.

If you are unsure how to verify proper ground of equipment in the checkstand ask a qualified electrician to

review the equipment installation.

4.3 in.(+/- 0.01)

110.0 mm (+/- 0.25)

2

.4 in

.(+

/- 0.01)

62

.0

mm (+

/-

0.25)

1.

2 in

.(

+/-

0

.0

1)

62.0 mm

(+/- 0.25)

NOTE

In an effort to eliminate a possible safety hazard all metal parts of a metal checkstand must be electrically

grounded.

Summary of Contents for MP6000

Page 1: ...MP6000 INTEGRATOR GUIDE ...

Page 2: ......

Page 3: ...MP6000 INTEGRATOR GUIDE 72E 172632 06 Revision A November 2014 ...

Page 7: ...v ...

Page 8: ...vi MP6000 INTEGRATOR GUIDE ...

Page 14: ...xii MP6000 INTEGRATOR GUIDE ...

Page 18: ...viii MP6000 INTEGRATOR GUIDE ...

Page 33: ...PRODUCT OVERVIEW AND FEATURES 1 15 ...

Page 34: ...1 16 MP6000 INTEGRATOR GUIDE ...

Page 41: ...HOST INTERFACES AND CABLE PINOUTS 2 7 USB Device Type continued IBM Table top USB ...

Page 42: ...2 8 MP6000 INTEGRATOR GUIDE USB Device Type continued IBM Hand held USB ...

Page 45: ...HOST INTERFACES AND CABLE PINOUTS 2 11 USB Device Type continued CDC COM Port Emulation ...

Page 55: ...HOST INTERFACES AND CABLE PINOUTS 2 21 RS 232 Host Types continued Standard RS 232 ...

Page 56: ...2 22 MP6000 INTEGRATOR GUIDE RS 232 Host Types continued ICL RS 232 ...

Page 58: ...2 24 MP6000 INTEGRATOR GUIDE RS 232 Host Types continued Wincor Nixdorf RS 232 Mode B ...

Page 59: ...HOST INTERFACES AND CABLE PINOUTS 2 25 RS 232 Host Types continued Olivetti ORS4500 ...

Page 60: ...2 26 MP6000 INTEGRATOR GUIDE RS 232 Host Types continued Omron ...

Page 61: ...HOST INTERFACES AND CABLE PINOUTS 2 27 RS 232 Host Types continued OPOS JPOS ...

Page 62: ...2 28 MP6000 INTEGRATOR GUIDE RS 232 Host Types continued Fujitsu RS 232 ...

Page 63: ...HOST INTERFACES AND CABLE PINOUTS 2 29 RS 232 Host Types continued CUTE 2 ...

Page 72: ...2 38 MP6000 INTEGRATOR GUIDE Third Party Scale continued Disable Third Party Scale 0 ...

Page 74: ...2 40 MP6000 INTEGRATOR GUIDE Third Party Scale LED Pin continued Active High 1 ...

Page 76: ...2 42 MP6000 INTEGRATOR GUIDE Third Party Scale Zero Pin continued Active High 1 ...

Page 79: ...HOST INTERFACES AND CABLE PINOUTS 2 45 IBM Port Addresses None Selected ...

Page 80: ...2 46 MP6000 INTEGRATOR GUIDE IBM Port Addresses continued Hand held Scanner Emulation Port 9B ...

Page 82: ...2 48 MP6000 INTEGRATOR GUIDE IBM Port Addresses continued Tabletop Scanner Emulation Port 17 ...

Page 84: ...2 50 MP6000 INTEGRATOR GUIDE IBM Scale Port Addresses continued Port 6A ...

Page 85: ...HOST INTERFACES AND CABLE PINOUTS 2 51 IBM Scale Port Addresses continued Port 6B ...

Page 86: ...2 52 MP6000 INTEGRATOR GUIDE IBM Scale Port Addresses continued Port 6E ...

Page 90: ...2 56 MP6000 INTEGRATOR GUIDE ...

Page 130: ...3 40 MP6000 INTEGRATOR GUIDE ...

Page 144: ...4 14 MP6000 INTEGRATOR GUIDE Legal Scale Units continued Pounds 1 ...

Page 148: ...4 18 MP6000 INTEGRATOR GUIDE Parameter 996 continued Low Vibration Sensitivity 1 ...

Page 150: ...4 20 MP6000 INTEGRATOR GUIDE Parameter 996 continued Ultra Low Vibration Sensitivity 3 ...

Page 154: ...4 24 MP6000 INTEGRATOR GUIDE ...

Page 188: ...A 8 MP6000 INTEGRATOR GUIDE ...

Page 192: ...B 4 MP6000 INTEGRATOR GUIDE ...

Page 208: ......

Page 209: ......