26/1

1/08 C0DN6000_EN

ENGLISH

ENGLISH

PUSH AND

TWIST

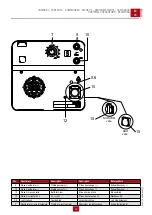

CONNECT WELDING CABLES

Insert the welding cable plugs completely in the sockets, turning

clockwise to lock them in place.

Connect the earth clamp to the negative pole and the electrode

holder to the positive.

+

Pay attention to the two polarities on the welding circuit,

which must not come into electrical contact with each other.

- Carefully tighten the output cables to the bushings; if loose,

they can cause problems of overheating and damage the

bushings, cables, etc.

- Make certain the grounding pincer is connected as near as

possible to the work station.

ADJUSTING THE WELDING CURRENT

The welding current is regulated by turning knob “T” conti-

nuously. If set to the minimum (turned fully in an anticlockwise

direction) it provides a current of approximately 30 A; if set to

the maximum (turned fully in a clockwise direction) it gives a

maximum current of approximately 200A (20V).

RECOMMENDED ELECTRODES

All the electrodes on the market can be used.

M

34

USE AS A WELDER

REV

.0-12/19

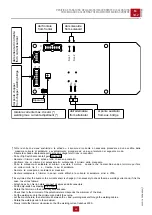

WARNING

A

reas for which access by non-authorized personnel is

forbidden

are:

- the control panel (at the front) - the endothermic motor

discharge.

!

ATTENTION

To reduce the risk of electromagnetic interference, keep the

welding cable length short and keep them on or near the

ground. If possible, welding operations should not be done

near sensitive electronic devices. If interference continues

to occur, adopt additional measures: shift the group, use

shielded cables, line filters, shield the entire work area.

If the above solutions do not suffice, consult our Technical

Servicing Department.

!

20

Summary of Contents for MAGIC WELD 200

Page 2: ......

Page 33: ...11 01 01 Note NOTE 33...

Page 34: ...11 01 01 Note NOTE 34...

Page 35: ......