C-22 CHUCKING

24)

Set "VALID" for CHUCK STROKE END (chuck jaw

stroke end detection function) using the cursor

control keys.

The status indicator

[CHCL]

is lit.

25)

Check for interference by following steps 13) to 15).

26)

After making sure that the spindle can be rotated

without interference, close the front door.

27)

Start the spindle manually.

28)

Set the required spindle speed.

Determine the spindle speed by considering the

soft jaw height, diameter to be cut, and the tool

material.

29)

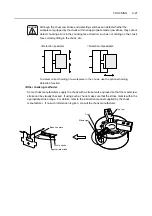

Feed the cutting tool on the Z-axis with the manual

pulse generator to bring it into contact with and

leave a cutting mark on the end faces of the three

soft jaws.

The diameter of the cutting mark must be larger

than the finishing diameter.

30)

Display the POSITION (RELATIVE) screen, and

reset the W coordinate value to "0".

31)

Move the O.D. cutting tool using the manual pulse

generator to bring it into contact with the outside

face of the soft jaw.

Ensure that the tool does not strike the soft jaw

or plug.

NOR

SPJ

STOP

REV

NOTE

Cutting mark

NOTE

CAUTION