Page 1 of 4: C31885 Rev B 10.03

1 Scope

These application notes are a guide to applying the G123-815

Buffer Amplifier. They tell you how to install, connect and

adjust the Buffer Amplifier. They do not tell you how to design

the closed loop system in which it is used.

2 Description

The G123-815 Buffer Amplifier interfaces between standard

PLC analogue input and output modules, on one side, and

a position transducer and a Moog valve, on the other.

It simplifies the use of a PLC in closing position loops.

The Buffer Amplifier solves the common problem of the

±10V PLC output being incompatible with the valve drive

requirements. It also provides digital noise filtering for the valve

signal and noise filtering for the position transducer signal.

For a more detailed description, see Moog brochure

G123-815E01.01.

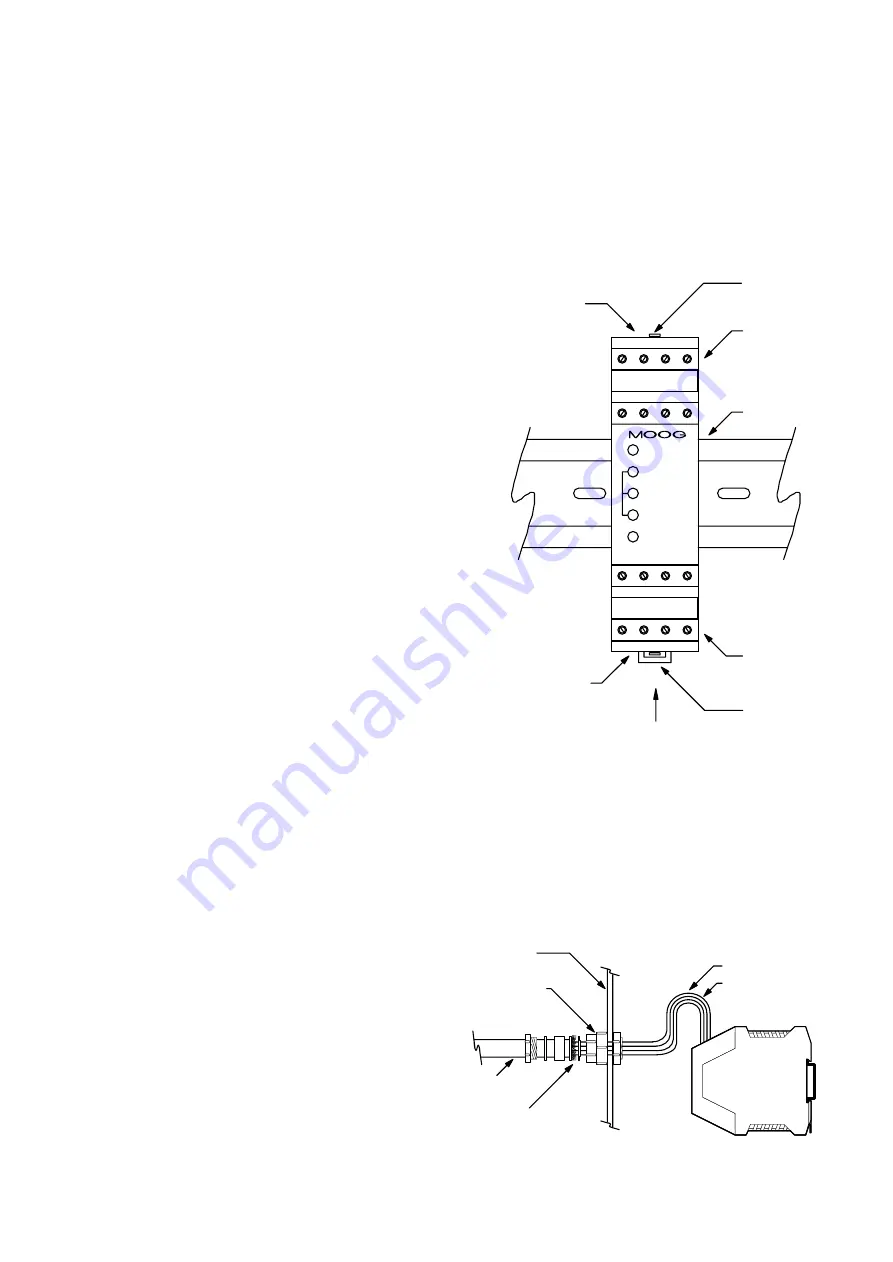

3 Installation

3.1 Placement

A horizontal DIN rail, mounted on the vertical rear surface of

an industrial steel enclosure, is the intended method of

mounting. The rail release clip of the G123-815 should face

down, so the front panel and terminal identifications are

readable and so the internal electronics receive a cooling

airflow. An important consideration for the placement of the

module is electro magnetic interference (EMI) from other

equipment in the enclosure. For instance, VF and AC servo

drives can produce high levels of EMI. Always check the EMC

compliance of other equipment before placing the G123-815

close by.

3.2 Cooling

Vents in the top and bottom sides of the G123-815 case

provide cooling for the electronics inside. These vents should

be left clear. It is important to ensure that equipment below

does not produce hot exhaust air that heats up the G123-815.

Buffer Amplifier

G123-815

3.3 Wiring

The use of crimp “boot lace ferrules” is recommended for the

screw terminals. Allow sufficient cable length so the circuit

card can be withdrawn from its case with the wires still

connected. This enables switch changes on the circuit card to

be made while the card is still connected and operating.

An extra 100mm, for cables going outside the enclosure,

as well as wires connecting to adjacent DIN rail units, is

adequate.

Application Notes

probe

Iv

valve

Vv

0V

BUFFER AMP

Bottom

vents

Cooling

airflow

release

Screw

terminals

Top vents

Screw

terminals

DIN rail

9 - 16

1 - 8

clip

Cover

release

tab (2)

DIN rail

1

2

3

4

9

10

11

12

5

6

7

8

13

14

15

16

cable gland

100mm Loop

Wires

Enclosure

Radial screen

termination

Cable

Grounded EMI

Preferred Wiring

m