Maintenance and inspection procedures 5-97

[Caution]

・ The brand name of the grease shown in the

is the grease put in at shipping.

・The lubrication time is a cumulative value of the operation at the maximum speed. If the operation has been sus

-

pended, or if the designated speed is slow, the lubrication time can be lengthened in proportion.

・ Depending on the robot operation state, the lubrication time will fluctuate, so determine the time according to

the state so that the grease does not run out.

・ By the maintenance forecast function of RT ToolBox2 (option) computes the guide of the lubrication hours put

together with the customer's operation status.

・ The numbers in the

correspond to the supply positions in

(RV-13F series).

・ When the specified time limit (24,000 Hr) is due, the overhaul work to replace internal grease is required. The

maintenance after it needs the overhaul work which replaces internal grease. Please ask dealer for more details

about overhaul.

(2) Lubrication method

1) Set the robot to the posture shown in

(RV-4F/7F series) or

2) Refer to the

Page 82, "5.3.2 Installing/removing the cover"

and remove the covers.

3) Please protect the timing belt with the cloth etc. so that the grease does not take for the timing belt at the

time of oil supply.

4) ・ RV-4F series

Remove the following screws, and install the attached grease nipples.

SExx01: J2 axis lubrication port <2>, J3 axis lubrication port <3>, J4 axis lubrication port <4>, J5 axis

lubrication port <5>, J6 axis lubrication port <6> (reduction gears) and J6 axis lubrication port <7>

(gear). Securely tighten the grease nipple by 4.7 N·m to 6.3 N·m

SExx02: J3 axis lubrication port <3>, J4 axis lubrication port <4>, J5 axis lubrication port <5>, J6 axis

lubrication port <6> (reduction gears) and J6 axis lubrication port <7> (gear). Securely tighten the

grease nipple by 4.7 N·m to 6.3 N·m

・ RV-7F series

Remove the following screws, and install the attached grease nipples.

SExx01: J2 axis lubrication port <2>, J4 axis lubrication port <4>, J5 axis lubrication port <5>, J6 axis

lubrication port <6> (reduction gears) and J6 axis lubrication port <7> (gear). Securely tighten the

grease nipple by 4.7 N·m to 6.3 N·m

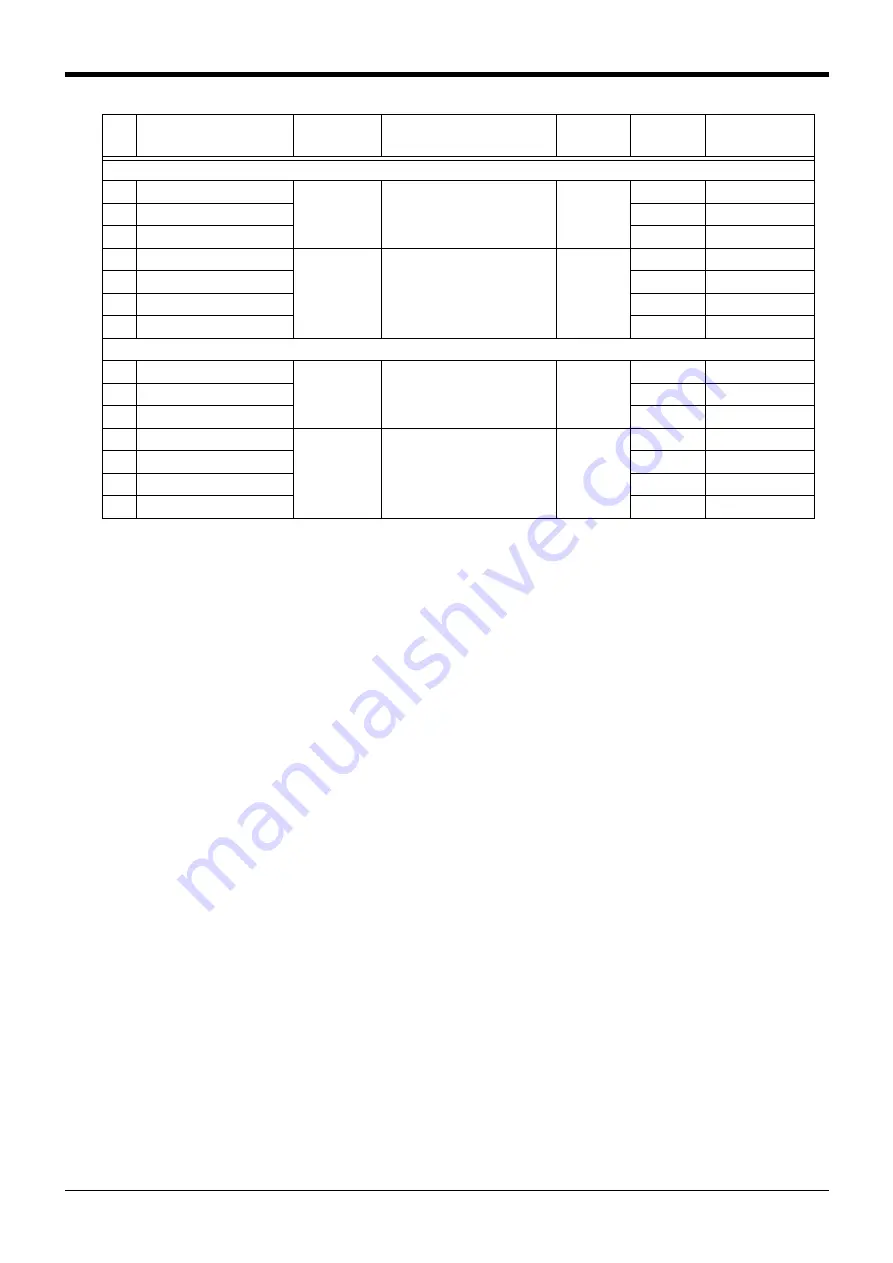

RV-7FLL

2

J1 axis reduction gears

Grease nipple

WA-110

VIGO GREASE

(Nabtesco Co., Ltd.)

20,000Hr

255g

Shoulder cover

4

J2 axis reduction gears

251g

6

J3 axis reduction gears

150g

7

J4 axis reduction gears

Grease nipple

WA-610

4B No.2

(Harmonic Drive Systems Inc.)

24,000Hr

7g

8

J5 axis reduction gears

2g

9

J6 axis reduction gears

2g

10

J6 axis gears

1.3g

Wrist cover

RV-13F/20F

2

J1 axis reduction gears

Grease nipple

WA-110

VIGO GREASE

(Nabtesco Co., Ltd.)

20,000Hr

255g

Shoulder cover

4

J2 axis reduction gears

251g

6

J3 axis reduction gears

150g

7

J4 axis reduction gears

Grease nipple

WA-610

4B No.2

(Harmonic Drive Systems Inc.)

24,000Hr

7g

8

J5 axis reduction gears

3g

9

J6 axis reduction gears

2g

10

J6 axis gears

1.5g

Wrist cover

Note1) When the screw is installed in the illustrated lubrication point, install the attached grease nipple and supply the grease.

No.

Parts to be lubricated

Note1)

Oiling method

Lubrication oil

(maker)

Lubrication

interval

Lubrication

amount

Cover to remove