7

GB

D

F

I

NL

E

P

GR

RU

TR

Dimension C

338

Dimension D

143

143+

α

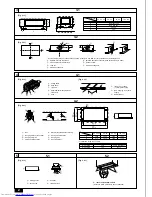

3.1. Securing installation and service space

[Fig. 3.1.1] (P.2)

•

Select a blowout direction suited for room shape, installation site and so on.

•

Piping, wiring and maintenance are all done on the bottom and the side. So,

secure the space given above for such work. Also, taking into consideration

serviceability and safety in hanging, secure as large space as possible.

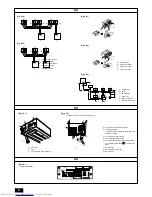

4. Fixing hanging bolts

4.2. Ceiling hole and hanging bolt positions

•

Use the gage supplied with the panel to fix hanging bolts so that the unit body

and ceiling hole are positioned in place as shown in the figure below. For how

to use the gage, refer to the instruction manual supplied with the panel.

Notes:

• The gage may expand or shrink with changes in the temperature and

humidity. First be sure to check the product dimensions, and then use

the gage.

• The ceiling hole is adjustable as shown in the figure below. Align the

centers of both ceiling hole and unit body so that the unit body is not

biased to the ceiling hole and that the gaps between the ceiling hole

edges and the unit body’s external dimensions come to be identical.

•

Use M10 hanging bolts (for all bolts). (field supply)

•

Each hanging bolt must extrude Cmm from the ceiling. It is possible to slide the

unit body 15 mm max. within part of the heights of the unit body and decorative

panel in order to make fine installation adjustments to the finished ceiling sur-

face. Sliding the unit body and incorporating a high-performance filter requires

the dimensions given in the figure below. To this, attach nuts which will fix a

hanging bracket as shown in the figure.

[Fig. 4.2.1] (P.2)

A

Nut

B

Washer (supplied with the unit body)

C

Hanging bolt ø10 (M10 screw)

D

Ceiling hole dimensions

E

Hanging bolt pitch

F

Hanging bolt

G

Finished ceiling surface

H

Hanging bracket

A

Split flow duct end connection

B

Split flow duct end connection (ø200 knockout on both sides)

C

Fresh air intake (ø150 knockout)

D

Fresh air intake

E

To be cut

F

4-ø2.9 mounting hole

G

4-ø2.9 mounting hole

Notes:

• Affixed on the back surface of each split flow duct end connection is

insulating material. Use a cutter knife to cut the insulating material along

the end connection.

• To adjust the fresh air intake capacity, cut the two places as shown in the

figure at right, and rotate the intake.

3.3. Combining indoor units with outdoor

units

For combining indoor units with outdoor units, refer to the outdoor unit installation

manual.

3.2. Split flow duct end connection - fresh

air intake

[Fig. 3.2.1] (P.2)

•

Knockouts are provided at each position as shown in the figure. Use them for

your purposes when installing the unit.

338+

α

(353 Max.)

•

α

indicates a range of 0 to 15 mm.

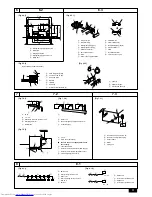

4.1. Fixing hanging bolts

(Use M10 hanging bolts. The bolts should be procured locally.)

(Give site of suspension strong structure.)

Hanging structure

•

Ceiling: The ceiling structure varies from building to one another. For detailed

information, consult your construction company.

1

Reinforcing the ceiling with additional members (edge beam, etc.) must be

required to keep the ceiling at level and to prevent the ceiling from vibrations.

2

Cut and remove the ceiling members.

3

Reinforce the ceiling members, and add other members for fixing the ceiling

boards.

For wooden construction

•

Use the tie beam (for one story building) or second-floor beam (for two story

building) as strength members.

•

To hang the air-conditioner, use a hard square timber of more than

6 cm if the distance between beams is less than 90 cm and a hard square

timber of more than 9 cm if the distance between beams is less than 180 cm.

[Fig. 4.1.1] (P.2)

A

Ceiling board

B

Edge beam

C

Tie beam

D

Square timber for hanging the air conditioner

E

Pitch

For reinforced concrete construction

•

As shown in the figure below, fix the hanging bolts, or use square timbers to fix

the hanging bolts.

[Fig. 4.1.2] (P.2)

F

Insert: 100 to 150 kg (1 piece) (field supply)

G

M10 hanging bolt (field supply)

H

Reinforcement

Product Weight (kg)

Model name 20 · 25 · 32

40 · 50

63 · 80

100 · 125

A

1060

1300

1650

2000

B

More than 1000

C

More than 500

D

Lap: 20

E

360

Model name

20 · 25

32

40

50

63

80

100 · 125

Body frame

24

25

33.5

35

39

41

56

Panel

7

7

8

8

10

10

11.5

Model name 20 · 25 · 32

40 · 50

63 · 80

100 · 125

A

1020

1260

1610

1960

B

816

1056

1406

1756

Installation

example

For not sliding unit body

For sliding unit body