318

10 CHARACTERISTICS

10.3 Dynamic brake characteristics

10.3

Dynamic brake characteristics

• Do not use dynamic brake to stop in a normal operation as it is the function to stop in emergency.

• For a machine operating at the recommended load to motor inertia ratio or less, the estimated number of

usage times of the dynamic brake is 1000 times while the machine decelerates from the rated speed to a

stop once in 10 minutes.

• Be sure to enable EM1 (Forced stop 1) after servo motor stops when using EM1 (Forced stop 1) frequently

in other than emergency.

• Servo motors for MR-J4 may have the different coasting distance from that of the previous model.

• The electronic dynamic brake operates in the initial state for the HG series servo motors of 600 W or smaller

capacity. The time constant "

" for the electronic dynamic brake will be shorter than that of normal dynamic

brake. Therefore, coasting distance will be longer than that of normal dynamic brake. For how to set the

electronic dynamic brake, refer to [Pr. PF06] and [Pr. PF12].

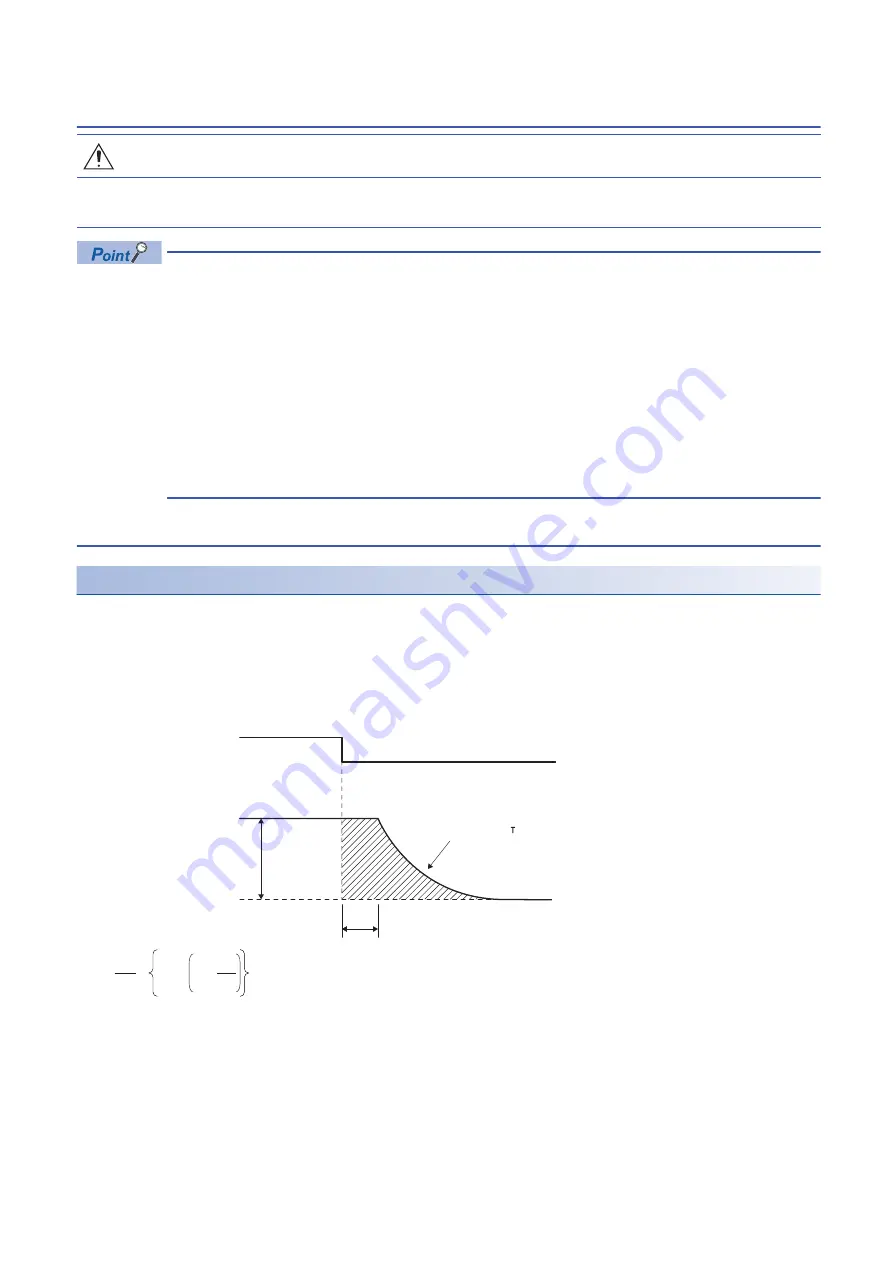

Dynamic brake operation

Calculation of coasting distance

The following shows the pattern in which the servo motor comes to a stop when the dynamic brake is operated. Use equation

10.2 to calculate an approximate coasting distance to a stop. The dynamic brake time constant

varies with the servo motor

and machine operation speeds.

Page 319 Dynamic brake time constant

A working part generally has a friction force. Therefore, actual coasting distance will be shorter than a maximum coasting

distance calculated with the following equation.

L

max

: Maximum coasting distance [mm]

V

0

: Machine's fast feed speed [mm/min]

J

M

: Moment of inertia of the servo motor [

10

-4

kg•m

2

]

J

L

: Load moment of inertia converted into equivalent value on servo motor shaft [

10

-4

kg•m

2

]

: Dynamic brake time constant [s]

t

e

: Delay time of control section [s]

CAUTION

• The coasting distance is a theoretically calculated value which ignores the running load such as friction. The calculated value will be longer than the actual

distance. If the braking distance is not longer than the calculated value, a moving part may crash into the stroke end, which is very dangerous. Install the anti-

crash mechanism such as an air brake or an electric/mechanical stopper such as a shock absorber to reduce the shock of moving parts.

V

0

OFF

ON

Machine speed

t

e

Time

EM1 (Forced stop 1)

Dynamic brake

time constant

J

M

t

e

+

τ

1 +

J

L

60

V

0

L

max

=

•

·········(10.2)

Summary of Contents for MELSERVO-J4 series

Page 2: ......

Page 605: ...APPX Appendix 6 EC declaration of conformity 603 A ...

Page 638: ...636 APPX Appendix 14 Encoder output pulse setting method MEMO ...

Page 645: ......