481

CHAPTER 11 MANUAL CONTROL

11

11.

2 JO

G

O

per

at

ion

11.2

JOG Operation

11.2.1

Outline of JOG operation

Use the hardware stroke limit function when carrying out JOG operation near the upper or lower limits. (

Section 12.4.4)

If the hardware stroke limit function is not used, the workpiece may exceed the movement range, and an accident may

result.

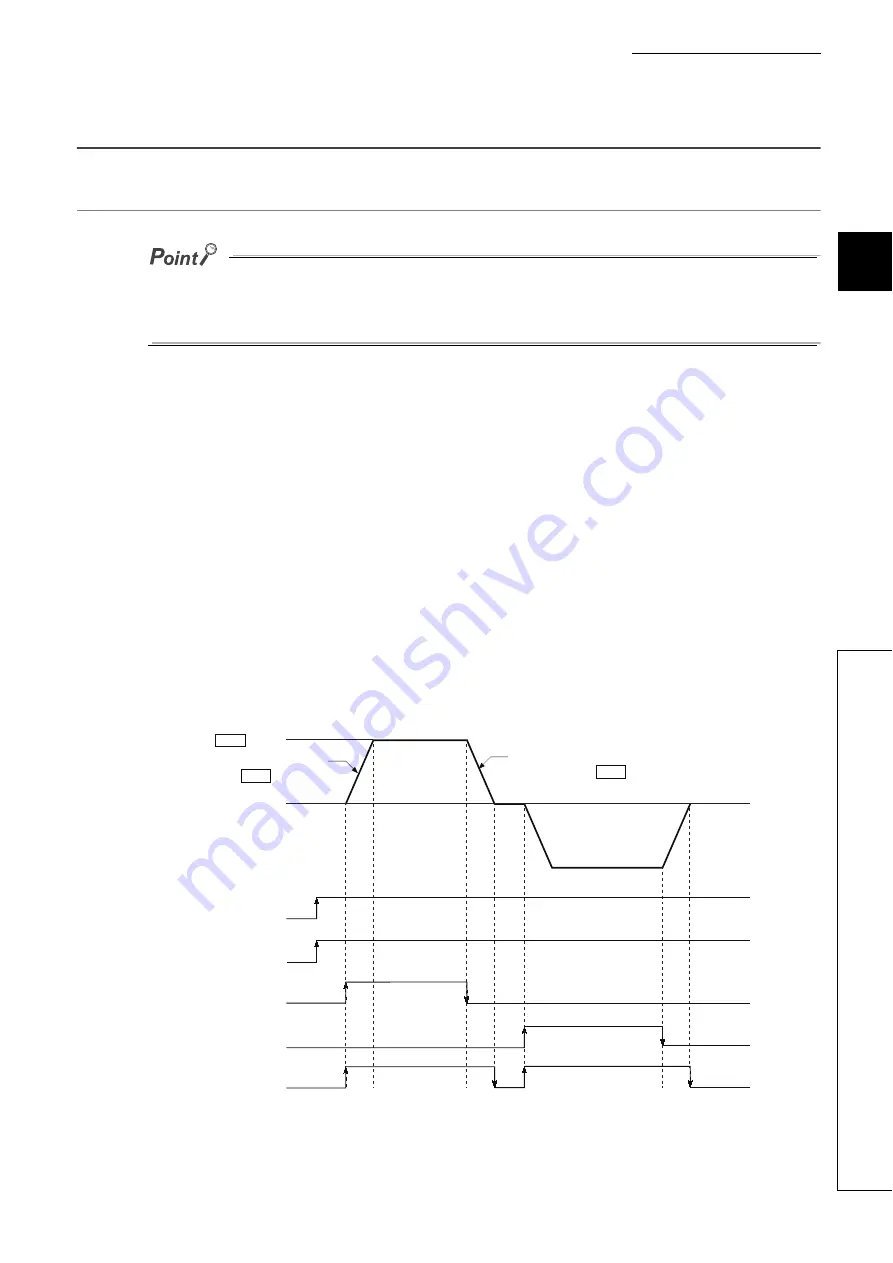

(1) JOG operation

In JOG operation, the Forward run JOG start signal [Y8, YA, YC, YE] or Reverse run JOG start signal [Y9, YB,

YD, YF] turns ON, causing pulses to be output to the drive unit from the LD75 while the signal is ON. The

workpiece is then moved in the designated direction.

The following shows examples of JOG operation.

1.

When the JOG start signal turns ON, acceleration begins in the direction designated by the JOG

start signal, and continues for the acceleration time designated in "[Pr.32] JOG operation

acceleration time selection". At this time, the BUSY signal changes from OFF to ON.

2.

When the workpiece being accelerated reaches the speed set in "[Cd.17] JOG speed", the

movement continues at this speed. The constant speed movement takes place at 2 and 3.

3.

When the JOG start signal is turned OFF, deceleration begins from the speed set in "[Cd.17] JOG

speed", and continues for the deceleration time designated in "[Pr.33] JOG operation deceleration

time selection".

4.

The operation stops when the speed becomes "0". At this time, the BUSY signal changes from ON

to OFF.

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Forward

JOG operation

Reverse JOG operation

JOG

speed

ON

OFF

1

2

3

4

Cd.17

Pr.32

Pr.33

PLC READY signal

[Y0]

LD75 READY signal

[X0]

Forward run JOG start signal

[Y8, YA, YC, YE]

Reverse run JOG start signal

[Y9, YB, YD, YF]

BUSY signal

[XC, XD, XE, XF]

Acceleration for the acceleration

time selected in

Deceleration for the deceleration

time selected in

Summary of Contents for MELSEC-L LD75D

Page 2: ......

Page 11: ...9 Memo ...

Page 176: ...174 ...

Page 264: ...262 ...

Page 266: ...264 ...

Page 267: ...265 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 268: ...266 ...

Page 269: ...267 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 270: ...268 ...

Page 271: ...269 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 272: ...270 Z ABRST1 instruction execution ...

Page 273: ...271 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 278: ...276 ...

Page 279: ...277 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 280: ...278 ...

Page 281: ...279 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 282: ...280 ...

Page 283: ...281 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 284: ...282 ...

Page 285: ...283 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 286: ...284 ...

Page 287: ...285 CHAPTER 6 PROGRAM USED FOR POSITIONING CONTROL 6 6 4 Positioning Program Examples ...

Page 316: ...314 Memo ...

Page 685: ...683 APPENDICES A Appendix 1 Function Update Appendix 1 1 Function comparison Memo ...

Page 738: ...736 Memo ...

Page 817: ......