15 - 50

15. INVERTER CONNECTION

15.6 Device Range that Can Be Set

15.6 Device Range that Can Be Set

The device ranges of controller that can be used for GOT

are as follows.

Note that the device ranges in the following tables are the

maximum values that can be set in GT Designer3.

The device specifications of controllers may differ

depending on the models, even though belonging to the

same series.

Please make the setting according to the specifications of

the controller actually used.

When a non-existent device or a device number outside

the range is set, other objects with correct device settings

may not be monitored.

Setting item

*1

The following shows the relation between the inverter station

numbers and the GOT data register.

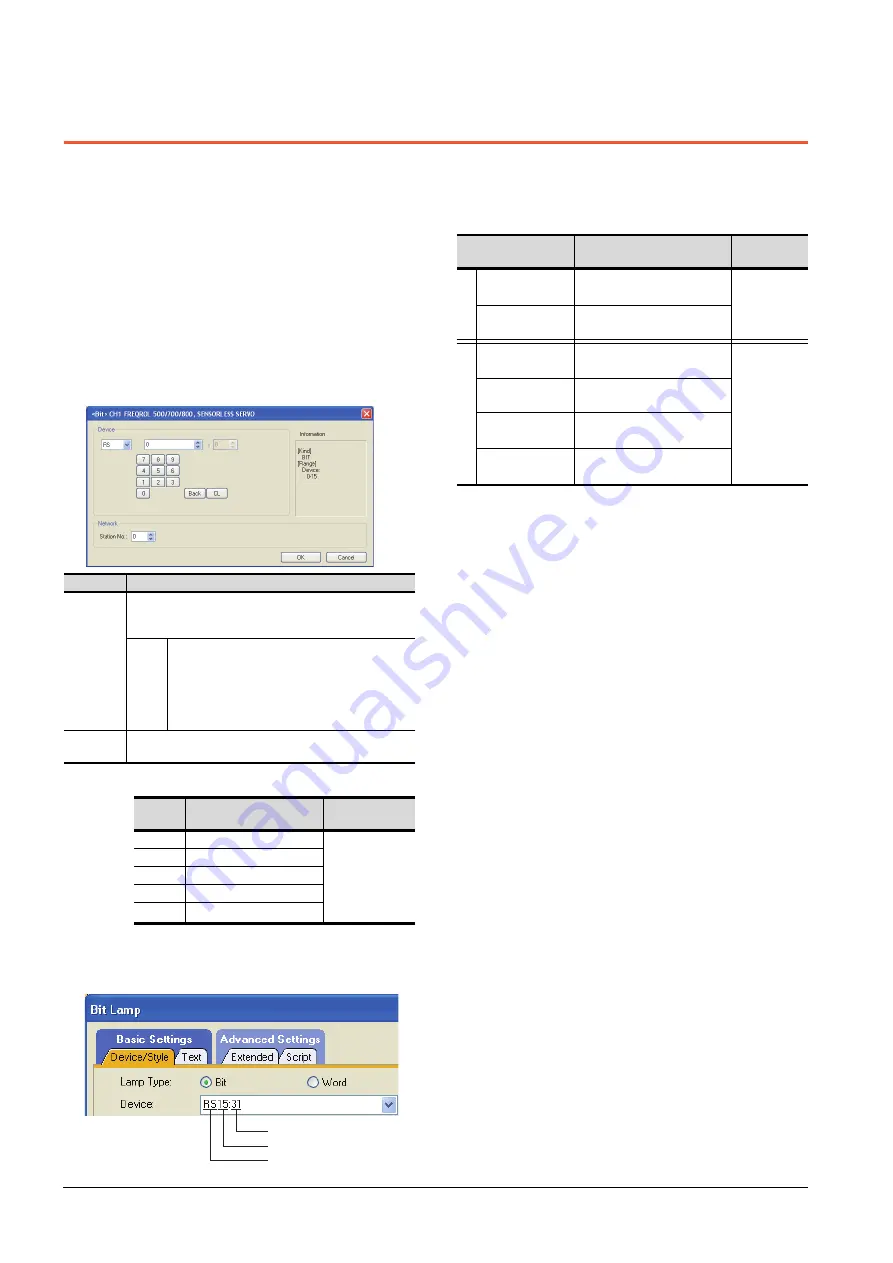

(1) Setting the device by inputting directly from the

keyboard

When setting the device by inputting directly from the

keyboard, set the items as follows.

Inverter (FREQROL 500/700/800 series),

sensorless servo (FREQROL-E700EX)

*1

When creating the screen, designate only either of

programmed operation (PG) device or parameter (Pr)

device.

Do no designate both PG (PG0 to PG89) and Pr (Pr900 to

Pr905) devices.

*2

Only 16-bit (1-word) designation is possible.

*3

Only reading is possible.

*4

Precautions for PU operation mode

When the GOT is connected to the PU connector and the

operation mode is set to the PU operation mode, the multi-

speed operation (W3 to W7, SP121, SP122) cannot be used.

For using the multi-speed operation, follow either of the

operations as below.

• Connect the GOT to the RS-485 terminal and set the

operation mode to the NET operation mode (Computer

link operation mode), and then operate the inverter.

• Change the motor speed with the set frequency (SP109,

SP110), and then operate the inverter with the forward or

reverse rotation (WS1, WS2, SP121, SP122).

*5

Precautions for WS devices

Only writing is possible for WS devices.

More than one WS cannot turn on at once.

(Except the turned on WS device, the other WS devices turn

off.)

Bits of SP122 (word device) and SP121 (word device) are

assigned to WS0 to WS7 and WS8 to WS15 respectively.

When more than one WS turns on at once, convert the

values for the bit devices that are assigned to the word

device into values for the word device. Write the converted

values into SP122 or SP121.

• Setting High speed operation command (WS5), Middle

speed operation command (WS4), and Low speed

operation command (WS3)

When setting High speed operation command (WS5),

Middle speed operation command (WS4), and Low speed

operation command (WS3), write numerical values to

device SP122 as necessary.

As the following figure shows, each operation mode is

assigned to device SP122.

The following shows an example for Forward rotation

command (WS1) and Low speed operation command

(WS3).

Item

Description

Device

Set the device name, device number, and bit number.

The bit number can be set only by specifying the bit of word

device.

Station

No.

Monitors the inverter of the specified station No.

0 to 31: To monitor the inverter of the specified

station No.

100 to 115: To specify the station No. of the inverter

to be monitored by the value of GOT data register

(GD).

*1

Information

Displays the device type and setting range which are

selected in [Device].

Station

No.

GOT data register (GD)

Setting range

100

GD10

0 to 31

(If setting a value

outside the

range above, a

device range

error occurs)

101

GD11

:

:

114

GD24

115

GD25

Station No.

Device number

Device name

Device name

Setting range

Device No.

representation

B

it device

Inverter status

monitor (RS)

*3

RS0: 0

to

RS15: 31

RS0: 100

to

RS15: 115

Decimal

Run command

(WS)

*4*5

WS0: 0

to

RS15: 31

WS0: 100

to

RS15: 115

W

o

rd

de

vi

ce

Alarm definition

(A)

*2*3

A0: 0

to

A7: 31

A0: 100

to

A7: 115

Decimal

Parameter (Pr)

*1*2

Pr0: 0

to

1500: 31

Pr0: 100

to

1500: 115

Programmed

operation(PG)

*1*2

PG0: 0

to

PG89: 31

PG0: 100

to

PG89: 115

Special parameter

(SP)

*2*4*5

SP108: 0

to

SP127: 31

SP108: 100 to

SP127: 115

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......