10. Safety system

MiR1000 Shelf Lift User Guide (en) 12/2020 - v.2.1 ©Copyright 2019-2020: Mobile Industrial Robots A/S.

103

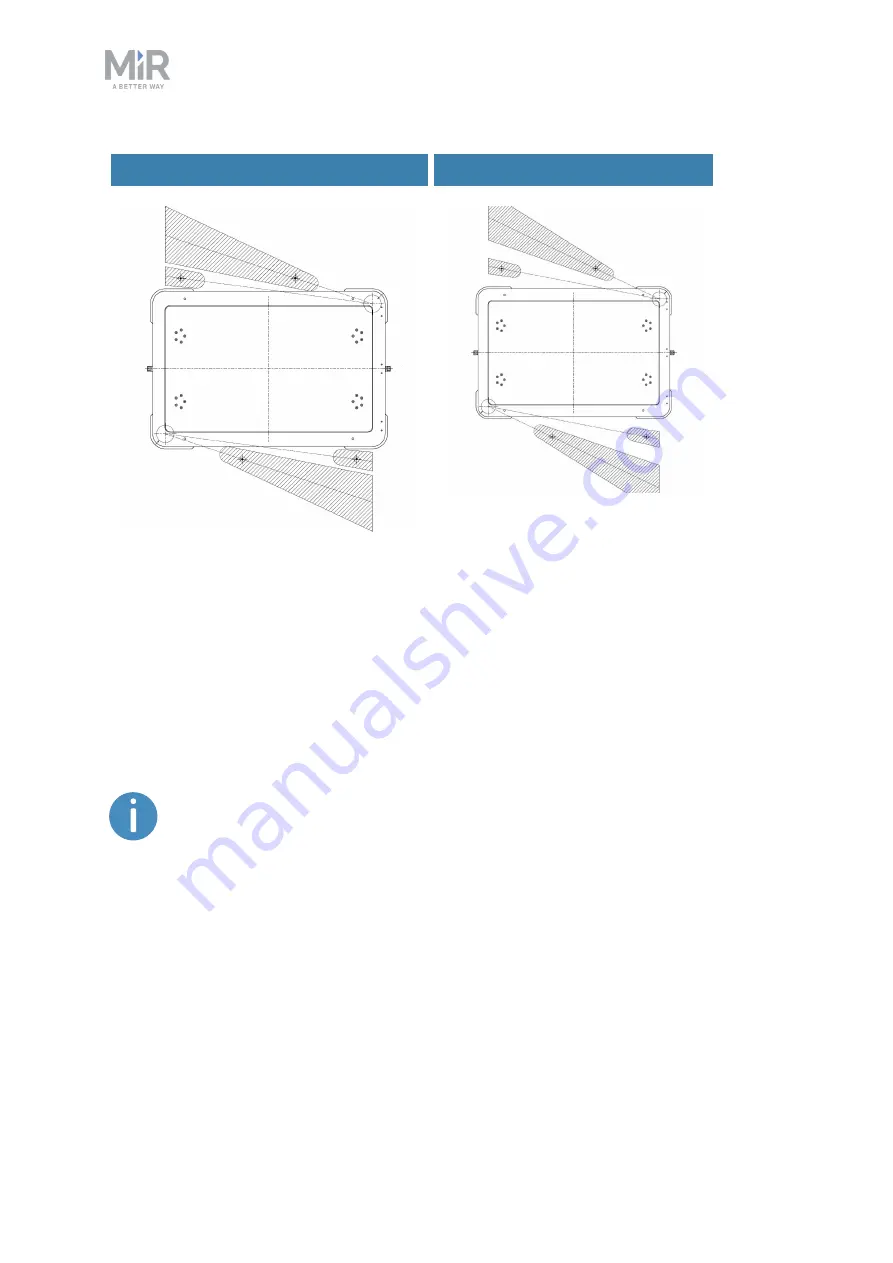

Narrow asymmetric shelf

Wide asymmetric shelf

Figure 10.10. The illustrations shows the blind spots around the shelf legs in the Protective fields when the

robot is carrying an asymmetric shelf. The blind spots are smallest when using asymmetric shelves.

By default, the shelf specific Protective field sets are designed for asymmetric shelves with

dimensions supported by MiR—see

Shelf specifications on page 112

. This design minimizes

the blind spots at the most critical areas. If you are using shelves that are not supported by

MiR's design guidelines, the Protective field sets must be changed and the safety system

recertified—see

Adjusting the Protective field sets on page 117

.

Shelves with symmetric legs create significantly larger blind spots for the

robot than shelves with asymmetric legs because the legs interfere more with

the field of view of the laser scanners.

The lift uses input pins 11 and 12 in the Auxiliary safety functions interface to signal whether

the lift is raised or lowered—see

Interface specifications on page 225

. These two input pins

are connected to the 24 V output in pins 1 and 2 through the mechanical switches in the lift.

When the lift is lowered, the switches are pressed down and closes the circuit so 24 V is

delivered to pins 11 and 12. When the lift is raised, the input pins receive 0 V.