MAINTENANCE SCHEDULE

Daily Weekly

Monthly

Yearly

Charge Batteries

Check Each Battery

Cell(s) Water Level

Lubrication – Grease

Fittings, chains, etc.

Check Carbon Brushes

Check/Clean Tanks &

Hoses

Inspect Scrub Housing

Skirts

Check/Clean/Rotate the

Brushes/Pads

Inspect and Clean

Solution Filter

Check/Clean the

Squeegee

Check Foot/Parking

Brake for Wear &

Adjustment

Check/Clean Vacuum

Shut-Off Float

Clean Spray jets on

Cylindrical System

Check/Clean the

Vacuum Motor Foam

Filter

Clean Hopper on

Cylindrical System

•

Have Minuteman check the vacuum motor carbon motor brushes once a year or after 300

operating hours. The brush motor carbon brushes should be checked every 500 hours or once

a year.

NOTE:

Refer to the Service Manual for more detail on maintenance and service repairs.

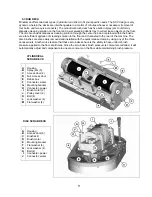

LUBRICATING THE MACHINE

Regularly scheduled lubrication of certain machine parts should be performed to insure trouble-free

operation of the machine.

Apply a generous amount of grease into the fittings on the machine until grease

seeps out around the bearings.

The grease points are listed below:

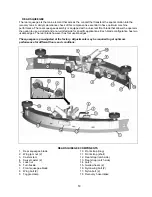

Rear squeegee caster wheel axle (2)

Rear squeegee caster wheel stem (2)

Side squeegee caster wheel axle (2)

Side squeegee caster wheel stem (2)

Steering wheel chain sprockets and idlers

Apply lubricant or light machine oil to lubricate the:

Rear squeegee general pivot points

Side squeegee general pivot points

Scrub deck linkages

Drive wheel assembly seals.

20

Summary of Contents for SCV28

Page 1: ...SCV 28 32 RIDER SCRUBBER OPERATION SERVICE PARTS CARE ...

Page 3: ...3 ...

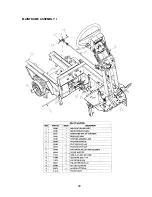

Page 31: ...EXPLODED VIEWS MAIN ASSEMBLY I 25 ...

Page 32: ...26 ...

Page 33: ...MAIN ASSEMBLY II 27 ...

Page 34: ...28 ...

Page 35: ...MAINFRAME ASSEMBLY I 29 ...

Page 36: ...MAINFRAME ASSEMBLY II 30 ...

Page 37: ...31 ...

Page 38: ...FRONT DRIVE ASSEMBLY 32 ...

Page 39: ...33 ...

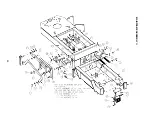

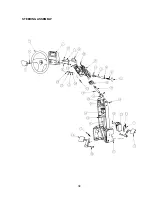

Page 40: ...STEERING ASSEMBLY 34 ...

Page 41: ...35 ...

Page 42: ...LCD HOUSING ASSEMBLY 36 ...

Page 43: ...SOLUTION TANK ASSEMBLY 37 ...

Page 44: ...38 ...

Page 45: ...ELECTRICAL PANEL ASSEMBLY 39 ...

Page 46: ...CONSOLE ASSEMBLY 40 ...

Page 47: ...RECOVERY TANK ASSEMBLY I 41 ...

Page 48: ...42 ...

Page 49: ...RECOVERY TANK II 43 ...

Page 50: ...DIVERTER ASSEMBLY 44 ...

Page 51: ...BATTERY BOX ASSEMBLY 45 ...

Page 52: ...PUMP ASSEMBLY 46 ...

Page 53: ...47 ...

Page 54: ...REAR AXLE ASSEMBLY 48 ...

Page 55: ...SQUEEGEE MECHANISM ASSEMBLY 49 ...

Page 56: ...REAR SQUEEGEE ASSEMBLY 28 50 ...

Page 57: ...51 ...

Page 58: ...REAR SQUEEGEE ASSEMBLY 32 52 ...

Page 59: ...53 ...

Page 60: ...28 CYLINDRICAL SCRUB DECK ASSEMBLY 54 ...

Page 61: ...55 ...

Page 62: ...28 DISC SCRUB DECK ASSEMBLY 56 ...

Page 63: ...57 ...

Page 64: ...32 CYLINDRICAL SCRUB DECK ASSEMBLY 58 ...

Page 65: ...59 ...

Page 66: ...32 DISC SCRUB DECK ASSEMBLY 60 ...

Page 67: ...61 ...

Page 68: ...CYLINDRICAL DECK AND SIDE SQUEEGEE MOUNTING 62 ...

Page 69: ...63 ...

Page 70: ...DISC SCRUBDECK AND SIDE SQUEEGEE MOUNTING 64 ...

Page 71: ...65 ...

Page 72: ...28 SIDE SQUEEGEE RIGHT SIDE 66 ...

Page 73: ...28 SIDE SQUEEGEE LEFT SIDE 67 ...

Page 74: ...32 SIDE SQUEEGEE RIGHT SIDE 68 ...

Page 75: ...32 SIDE SQUEEGEE LEFT SIDE 69 ...

Page 76: ...OFF AISLE WAND ASSEMBLY 70 ...

Page 77: ...71 ...

Page 78: ...PLUMBING DIAGRAM 72 ...

Page 79: ...WIRING DIAGRAMS POWER WIRING 73 ...

Page 80: ...INPUTS TO CONTROLLER 74 ...

Page 81: ...OUTPUTS FROM CONTROLLER 75 ...

Page 82: ...KEYBOARD WIRING 76 ...

Page 83: ...MACHINE SCHEMATIC 77 ...

Page 84: ...1 03 78 ...