T1

2.1

2

SECTION 2

SECTION 2

SECTION 2

SECTION 2

SECTION 2

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

Page

Page

Page

Page

Page

2-1

Unloading the machine ................................................................................................................ 2.2

2-2

Fitting the demounted parts ........................................................................................................ 2.4

2-2.1

Fitting the additional tables (

) ............................................................................. 2.4

2-3

Electric connection ........................................................................................................................ 2.6

2-4

Connection to the suction system ............................................................................................... 2.8

2-5

Safety devices ................................................................................................................................. 2.9

Summary of Contents for FORMULA T1

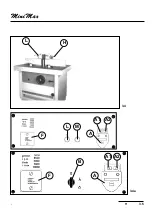

Page 22: ...T1 2 3 2 2 1 2 2 kg _____ 475 ...

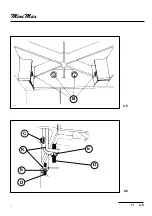

Page 24: ...T1 2 5 2 2 6 2 5 B T13216 E D E K D C ...

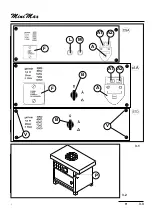

Page 26: ...T1 2 7 2 MORSE1 L1 L2 L3 N PE P 2 7 ...

Page 29: ...INSTALLATION 2 10 T1 BF NGB2 ...

Page 32: ...T1 3 3 3 A1 A2 F L M A A1 A2 B A F B V V 3 1 P 3 2 ...

Page 34: ...T1 3 5 3 L H 3 4 A1 A2 F L M A A1 A2 B A F 3 4a ...

Page 35: ...MACHINE SETTING AND USE 3 6 T1 BF NGB3 ...

Page 38: ...T1 7 3 7 7 2 7 3 ALBE1 ALBE2 D B S A C B A Z T 7 1 A F P bf7 4 ...

Page 40: ...T1 7 5 7 B A 7 4 ...

Page 42: ...T1 7 7 7 7 6c 7 6a 7 6b ...

Page 44: ...T1 7 9 7 7 7 7 8 L S N C G P H ...

Page 46: ...T1 7 11 71 L H A M P C 7 9 ...

Page 48: ...T1 7 13 71 7 13 REGISTR M 7 12 H M P L I T F R ...

Page 50: ...T1 7 15 71 CUFFI4 F R 7 14 7 15 I T REGISTR M H M P L ...