GENERAL

1.12

T1

BF-NGB1

13- Test working to check the tool adjustment may not be carried out without the guards required.

14- The working area shall have a good lighting and a sufficient room so that the operator is always

out of a dangerous area and so that no slipping danger may rise.

15- Start the working only when the tool has reached the right working speed.

16- In all milling operations, in which the piece kickback is possible particulary in case of interrupted

milling, you shall use antikickback devices.

In case of short pieces use template to guide the piece against the cutter.

17- When possible use a feeder.

MAINTENANCE SAFETY

1- When you stop the machine for carrying out adjustments or demounting any machine member,

turn main switch to zero and indicate it by a sign, then lock the main switch .

Make sure that the electric system of the machine is swichted off.

2- Completely stop the machine before cleaning or removing the guards for maintenance operations.

3- The general cleaning of the machine (in particular the worktable) and of the floor is an important

safety factor.

4- Use proper gloves for handling the tools.

Summary of Contents for FORMULA T1

Page 22: ...T1 2 3 2 2 1 2 2 kg _____ 475 ...

Page 24: ...T1 2 5 2 2 6 2 5 B T13216 E D E K D C ...

Page 26: ...T1 2 7 2 MORSE1 L1 L2 L3 N PE P 2 7 ...

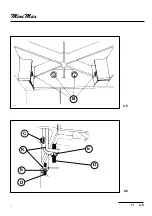

Page 29: ...INSTALLATION 2 10 T1 BF NGB2 ...

Page 32: ...T1 3 3 3 A1 A2 F L M A A1 A2 B A F B V V 3 1 P 3 2 ...

Page 34: ...T1 3 5 3 L H 3 4 A1 A2 F L M A A1 A2 B A F 3 4a ...

Page 35: ...MACHINE SETTING AND USE 3 6 T1 BF NGB3 ...

Page 38: ...T1 7 3 7 7 2 7 3 ALBE1 ALBE2 D B S A C B A Z T 7 1 A F P bf7 4 ...

Page 40: ...T1 7 5 7 B A 7 4 ...

Page 42: ...T1 7 7 7 7 6c 7 6a 7 6b ...

Page 44: ...T1 7 9 7 7 7 7 8 L S N C G P H ...

Page 46: ...T1 7 11 71 L H A M P C 7 9 ...

Page 48: ...T1 7 13 71 7 13 REGISTR M 7 12 H M P L I T F R ...

Page 50: ...T1 7 15 71 CUFFI4 F R 7 14 7 15 I T REGISTR M H M P L ...