5

Installation

5.1

Prior to mounting

5.1.1

Preparing the foundation/substructure

-

The foundation for the mounting kit must be horizontal (use spirit level), flat, and

rigid for the intended loads.

-

The load distribution on the available load cells must be as even as possible to

prevent overload of the individual load cells.

-

The substructure foundations/supporting surfaces for the mounting kits should be at

the same level, and the supporting surfaces of the weighing object (e.g. vessel feet)

must be arranged in parallel.

-

For screw mounting of the upper and lower plates

:

-

Generate the drilling pattern of the lower plate of the mounting kit (see

Chapter

) according to the weighing system arrangement on the foundation/

substructure.

-

Generate the drilling pattern of the upper plate of the mounting kit (see

Chapter

) according to the weighing system arrangement for each vessel lug

or vessel foot.

-

If soft filler layers (e.g. made from rubber or plastic material) are used between the

mounting kit and vessel/or between the mounting kit and substructure for vibration

dampening or for temperature insulation, a load compensating plate must be

provided between this soft filler layer and the mounting kit to ensure even load

application into the mounting kit.

The design of the insulation and compensation plates depends on the respective

application.

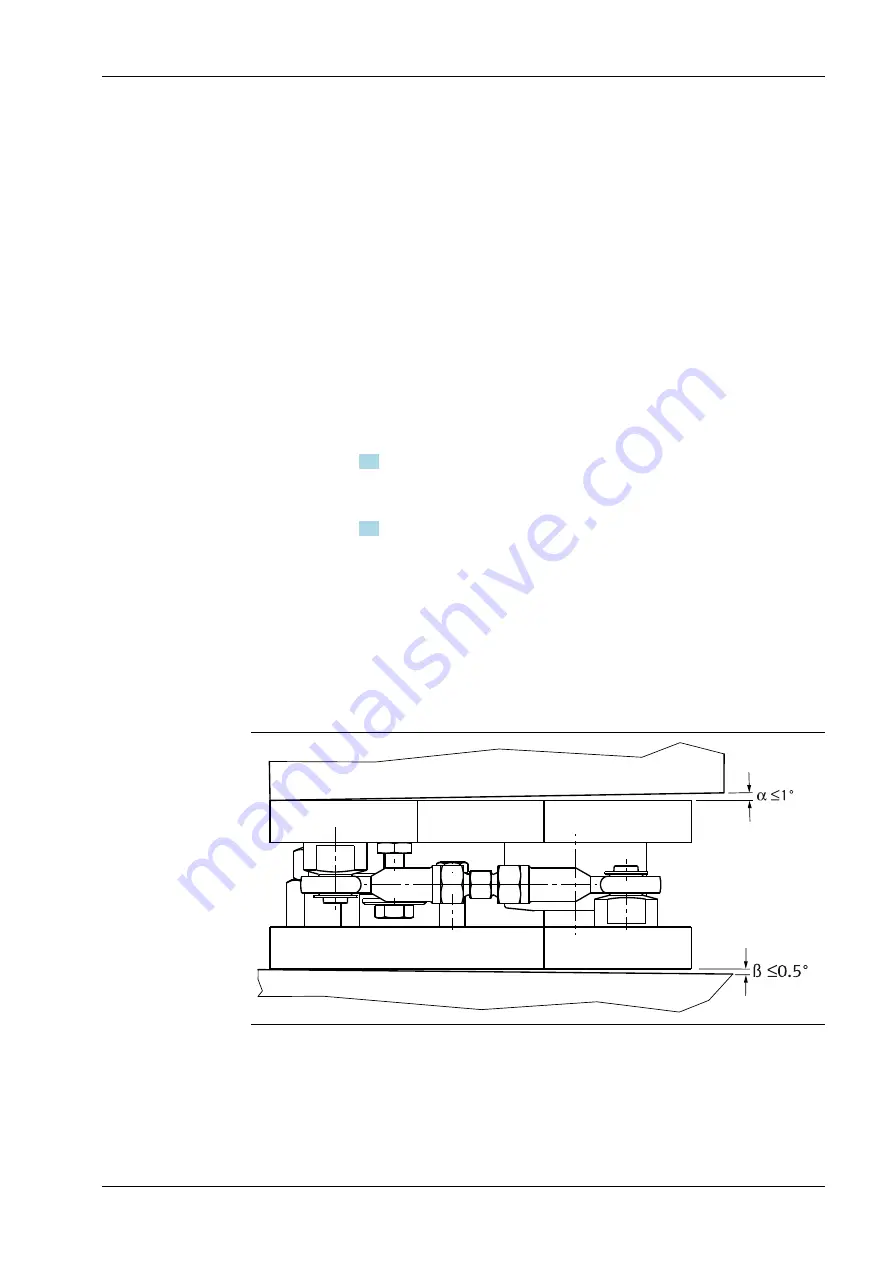

The maximum permissible inclination must be strictly observed in order to keep the

impact on the measuring accuracy to a minimum (see figure).

5 Installation

Maxi FLEX and Maxi FLEXLOCK mounting kits PR 6012/02, ../32, ../42

Minebea Intec

EN-19