Chapter 3 Setup

3-7

3

2

2

6

Check the correction pattern and enter a

correction value.

• A screen for entering the correction value

appears.

•

Enter a correction value in “+”

:

The boundary between the two bands is widened.

•

Enter a correction value in “-”

:

The boundary between the two bands is

narrowed.

• When you change the correction value by “25”,

the width of the boundary changes by about 0.1

mm.

7

Press

key.

• Print a correction pattern again and check it.

• When media correction is needed, perform the

operation in Step 6 to make correction.

8

Press

key several times to end

the setting.

Correcting Media-feeding during

Printing

A media-feeding rate can be corrected even in the remote

mode or when image data is printed.

1

Press the

(ADJUST)

in the Remote.

2

Press

to enter a corrected

feeding rate.

•

Corrected feeding rate

: -9999 to 9999

• The value entered here is reflected in the corrected

feeding rate soon.

3

Press

key.

• The changed value is registered.

If the Positions of Dots Shift...

When the condition for printing (Distance of the platen and

the head /media thickness/media type/etc.) has been

changed, perform the following operation to correct the

ink drop position for bidirectional (Bi) printing and obtain

the proper printing result.

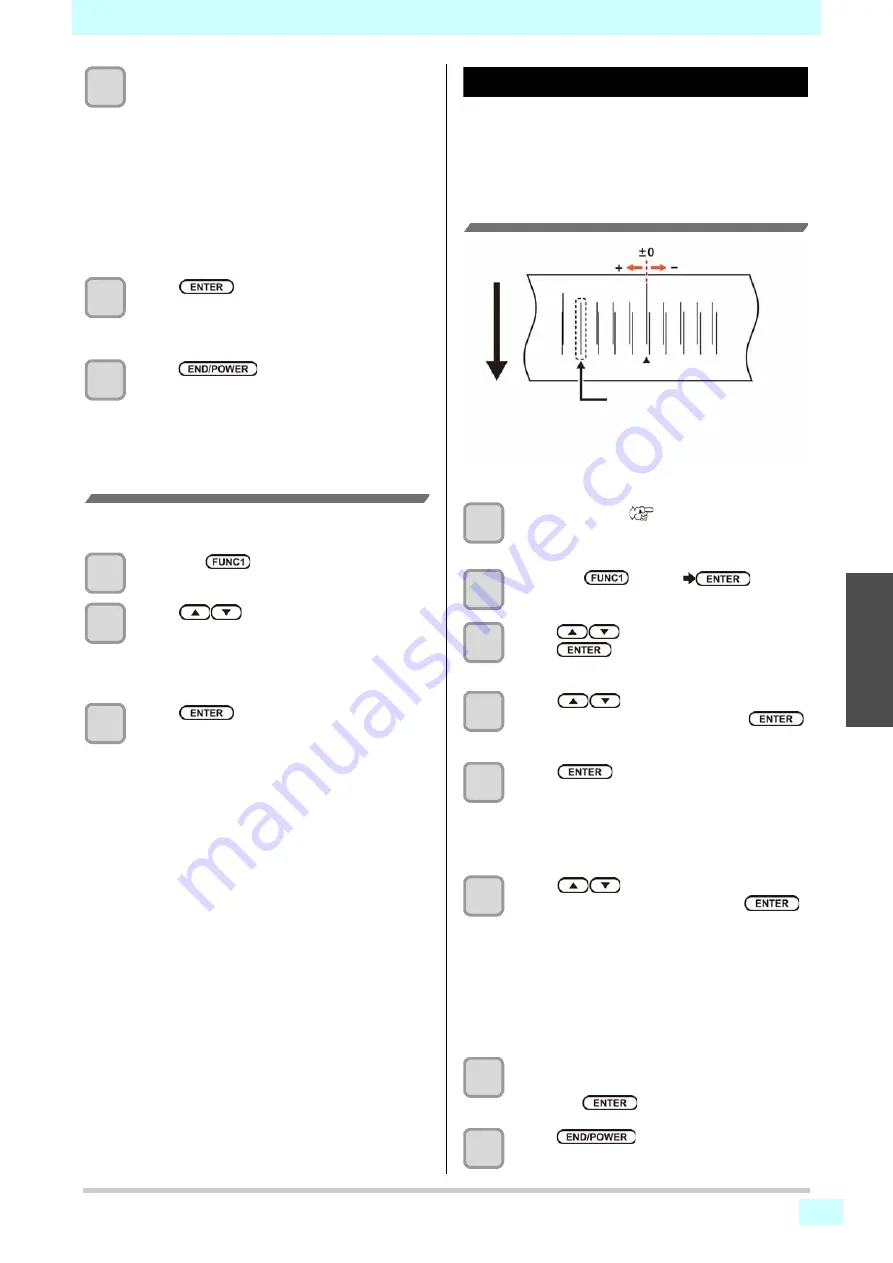

Example of a Printed Pattern

1

Setting a Media (

• In order to print a pattern, a media that is 500 mm

wide at least is necessary.

2

Press the

(MENU)

key in

Local.

3

Press

to select SETUP 1 to 4, and

press

key.

• Setup menu will be displayed.

4

Press

to select

“DropPos.Correct” , and press the

key.

5

Press

key.

• Printing of the Drop position correct printed

pattern will start.

• Multiple test patterns are printed. (The printed

patterns are called Pattern 1, Pattern 2 in the

order of printing.)

6

Press

to enter the correction

value for pattern 1, and press the

key.

•

Corrected feeding rate

: -40 to 40

• Check the test patterns. The position where an

outward feeding line and a return feeding line

become one straight line is the correction value.

• When the correction value in not between -40 and

40, adjust the height of the printing heads and

then perform the operations in Step 2 and later.

7

In the same way as step 6, enter the

correction value for patterns 2 to 5, and

press the

key.

8

Press

key several times to end

the setting.

The dots at the fourth position

counted from the zero position in

the positive direction form a

straight line.

In this case, the dot position

correction value is 4.0.

Output

direction