2-21

2

2

2

2

Correct the ink drop

position for bidirec-

tional printing

When the condition for printing (media thickness/ink type/

etc.) has been changed, perform the following operation

to correct the ink drop position for bidirectional (Bi)

printing and obtain the proper printing result.

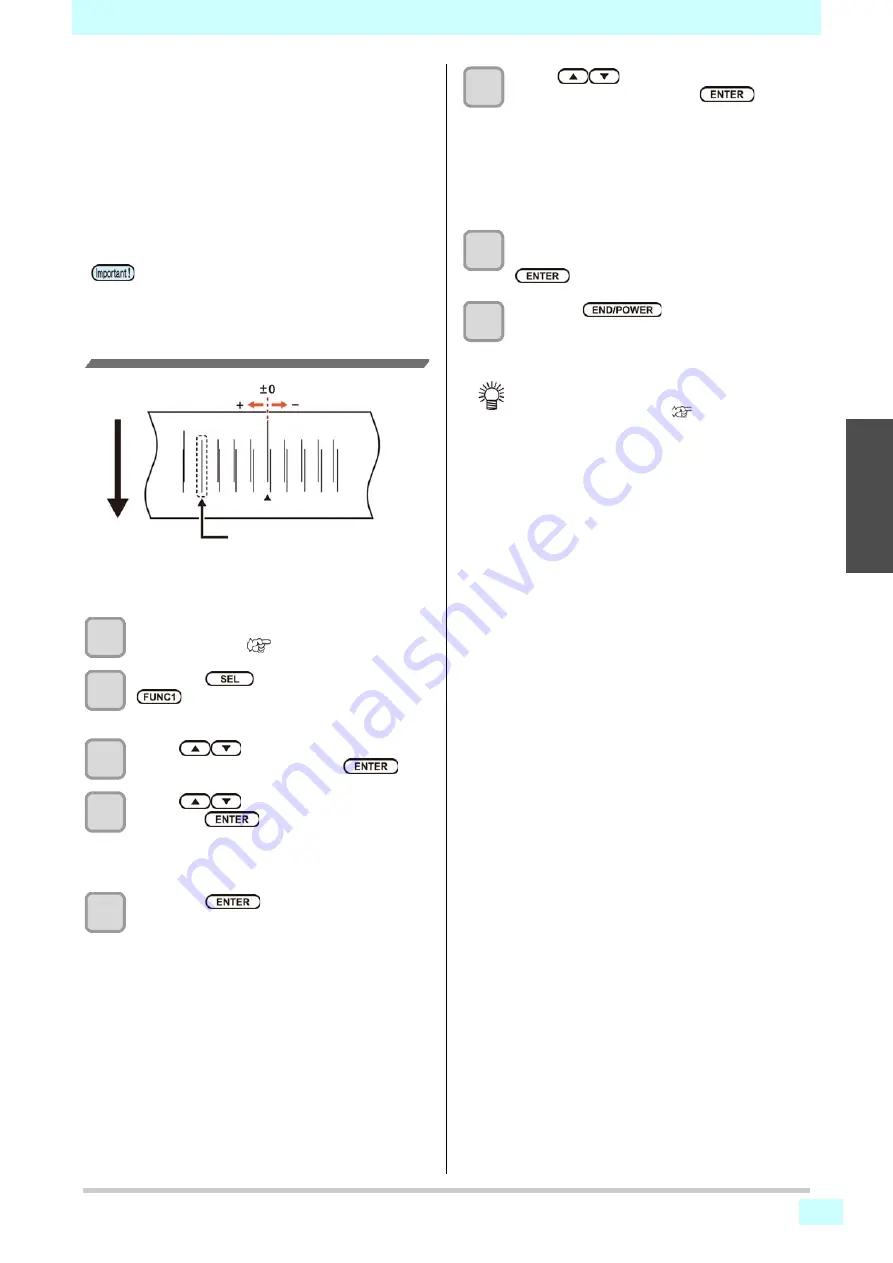

Example of a Printed Pattern

1

Set a media on the machine and set a

printing origin. (

2

Press the

key, and press the

(ADJUST)

in LOCAL.

• ADJUST MENU appears.

3

Press

to select “DROP.

POScorrect”.” , and press the

key.

4

Press

to select resolution, and

press the

key.

•

Resolution

: 300dpi/450dpi/600dpi/900dpi

• Perform correction for printing resolutions (Y

direction).

5

Press the

key.

• Printing of the Drop position correct printed

pattern will start.

• Multiple test patterns are printed. (The printed

patterns are called Pattern 1, Pattern 2 in the

order of printing.)

6

Press

to enter a correction value

of Pattern 1, and press the

key.

• Corrected feeding rate: -40 to 40

• Check the test patterns. The position where an

outward feeding line and a return feeding line

become one straight line is the correction value.

• When the correction value in not between -40 and

40, adjust the height of the printing heads and

then perform the operations in Step 2 and later.

7

In the same way as in Step 6, enter a

correction value of Pattern 2, and press the

key.

8

Press the

key several times to

end the setting.

• When using leaf media, set a media of more than

210mm put horizontally. If a media with narrow

width is set, printing will only be conducted to

midway.

The dots at the fourth position counted

from the zero position in the positive

direction form a straight line.

In this case, the dot position correction

value is 4.0.

Output

direction

• You can select “DROP.POScorrect” by using the

[FUNCTION] key in the Local without pressing the

[FUNC2] (ADJUST) key. (