- 5.6 -

When medium thickness is changed [Print Adjust]

When the head height is adjusted, be sure to correct the dot positions.

This function corrects the dot positions to ensure that the accurate plotting result is obtained.

The dot positions are corrected by comparing the ink dropping positions on each of the seven test

patterns between the two plotting directions.

Always perform Print Adjust (dot position correction) whenever the head height is changed.

STEPS:

1.

Set a sheet of paper, use 297mm x 210mm or

larger size with the long side set horizontally,

and set the Origin.

2.

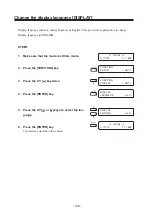

Select the [Print Adjust].

3.

Press the [ENTER] key.

4.

Press the [ENTER] key.

Plotting of the test patterns for the correction of dot position

starts. There are seven types of test patterns that are plotted.

5.

Press the XY [ ] or [ ] keys to correct the dot

position of pattern 1.

The seven test patterns that are output are sequentially

named [PATTERN 1] to [PATTERN 7].

Select the correct dot positions on [PATTERN 1] pressing the

XY [ ] or [ ] keys.

Select the dot positions that make a straight line on the test

pattern in the two plotting directions.

• If the pattern correction value for straight lines is

not within -15 t15, adjust the head height

and then correct it again with [Print Adjust].

MAINTENANCE

Print Adjust

< ent >

∗

∗

Printing

∗

∗

Please Wait

Print Adjust

Pattern

: ent

Print Adjust

Pattern1

= 4.0

Select the dot positions 4.0 that

make a straight line on the test

pattern in two plotting direction.

Summary of Contents for DM3-1810S

Page 2: ......

Page 20: ... xvi ...

Page 34: ... 1 14 ...

Page 76: ... 3 20 ...

Page 112: ... 6 10 ...

Page 131: ... A 19 TYPE Refresh Level3 TYPE mm inch mm X Level0 Level3 X inch Function flowchart ...

Page 141: ... A 29 MAIN Ver1 00 I F Ver Function flowchart ...

Page 144: ...D201258 1 10 30032007 ...

Page 145: ......

Page 146: ...PrintedinJapan MIMAKI ENGINEERING Co Ltd FW 5 10 NH ...