— A.16 —

D. SPECIFICATIONS

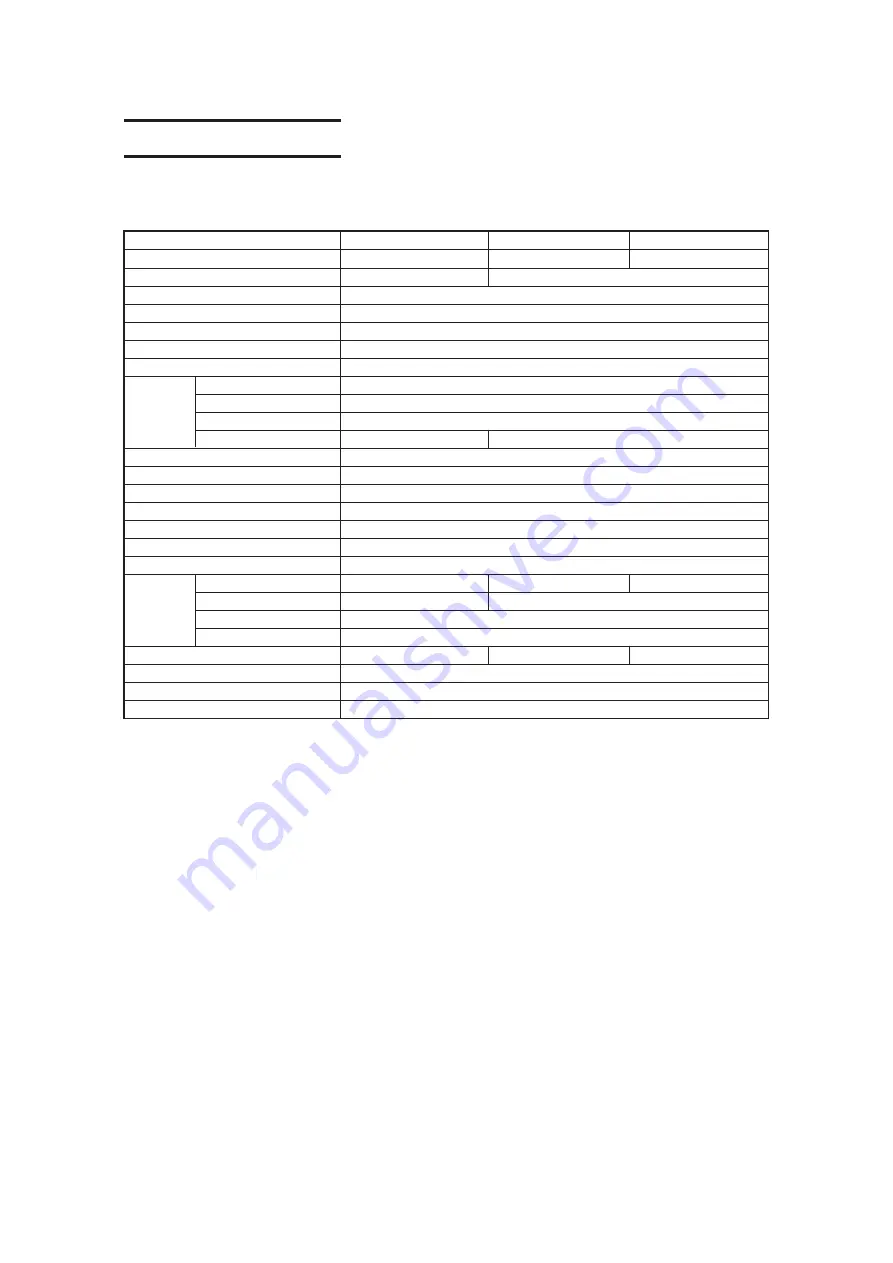

Basic specifications

Type

CF2-0912

CF2-1215

CF2-1218

Effective stroke X axis

1200

1500

1800

Y axis

900

1200

Driving method

X, Y, Z,

θ

4-axis DC software servo

Maximum speed

50 cm/s

Maximum acceleration

0.5 G

Mechanical resolution

X axis : 0.00234375 mm, Y axis : 0.003125 mm,

θ

axis : 0.05625

°

Command resolution

0.025 mm / 0.01 mm (switchable on operation panel)

Range accuracy

±

0.1 mm or

±

0.1% of travel distance, whichever is largest

Repeat accuracy

±

0.1 mm

Origin reproducibility

±

0.1 mm

Perpendicular accuracy

0.7 mm

0.9 mm

Work securing method

Vacuum suction by blower

Maximum set work thickness

20 mm

*2

Settable work weight

70 kg max. (point load)

Receiving buffer capacity

1MB

Command

MGL-IIc3 (MGL-IIc supported)

*3

Interface

RS-232C

Packing configuration

Main unit and pedestal separated and packed in one box; blower packed in separate box

Width

1757

2057

2357

Depth

1595

1895

Height

1100 (except cable guide)

Cutting panel surface height

Approx. 770

Main unit weight

140

165

180

Operating environment

5 to 40

°

C, 35 to 75% (Rh), no condensation

Input power supply

Main unit : 50/60 Hz AC 100/120/220/240 V (tap changing)

Power consumption

Main unit : 500VA Blower : Stated separately

Static ac-

curacy

*1

External

d i m e n -

sions

*1. This is the accuracy for pen writing with almost no load. The guaranteed temperature range is 20 to 25

°

C.

*2. This is the maximum thickness of works that can be set. This value differs from the maximum thickness that can be cut.

*3. This is a dedicated HP-GL command.

*4. A rush current flows when the blower is switched on. The capacitance is prescribed elsewhere.

Summary of Contents for CF2 Series

Page 48: ...1 32...

Page 120: ...3 24...

Page 138: ...4 18...

Page 176: ...A 12 C OUTPUT SAMPLES Cutting quality 1 Cutting quality 2...

Page 177: ...A 13 ASCII dump list Sample coated...

Page 178: ...A 14 Sample E corrugated Sample B corrugated...

Page 179: ...A 15 Circle cutting R 3 5 10 20 50 100 Parameter dump list R 3 R 5 R 10 R 20 R 50 R 100...

Page 185: ......

Page 186: ...D201402 1 30 16062008 MIMAKI ENGINEERING CO LTD 2008 EM FW 2 50...