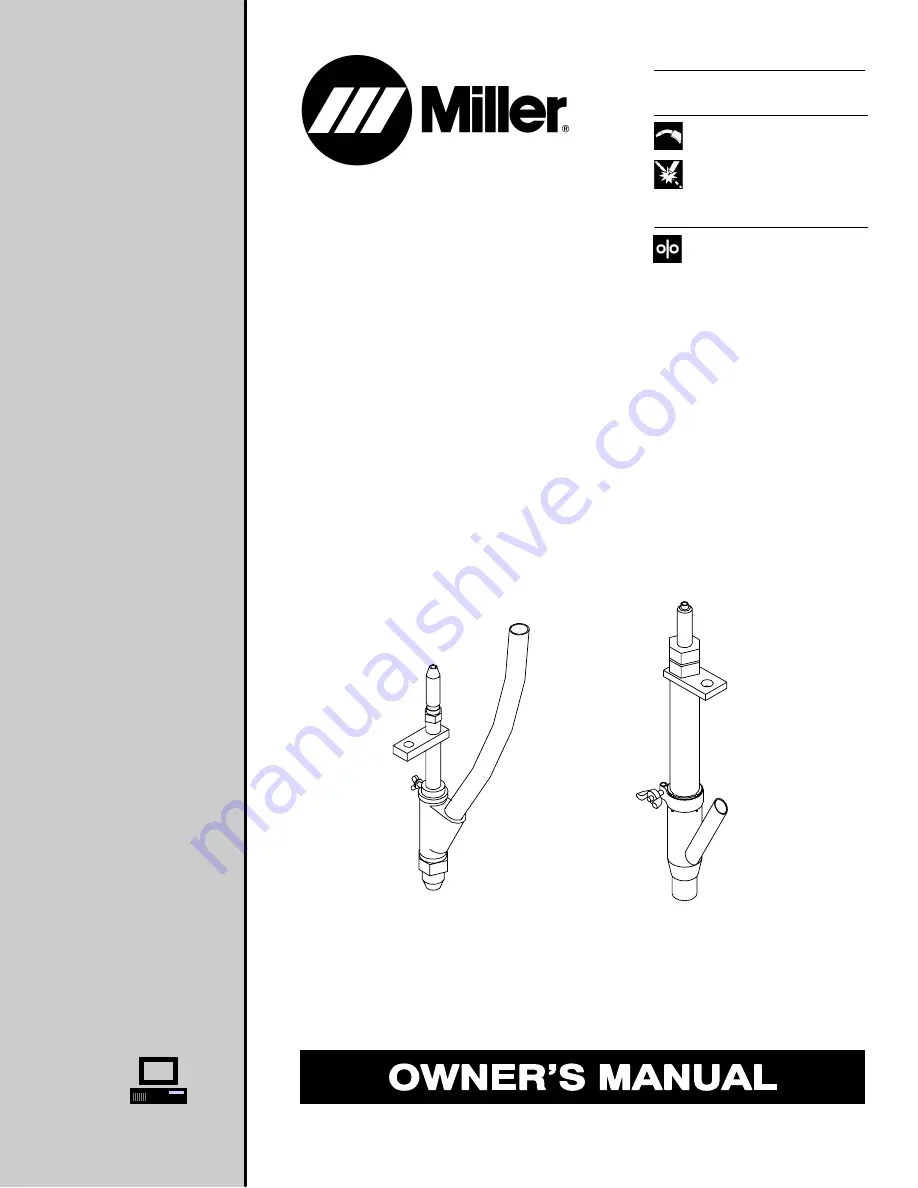

Torches for

Automated Applications

Process

OBT-600 And OBT- 1200

Submerged Arc Welding

(SAW)

OM-1596

192 709B

April 2003

Description

Torches For Automatic Welding Sys-

tems Using The Submerged Arc Weld-

ing (SAW) Process

Automatic Welding

Visit our website at

www.MillerWelds.com