2

3

ver. 1.00

IR eclipse click

™

manual

0 100000 027301

click

™

BOARD

www.mikroe.com

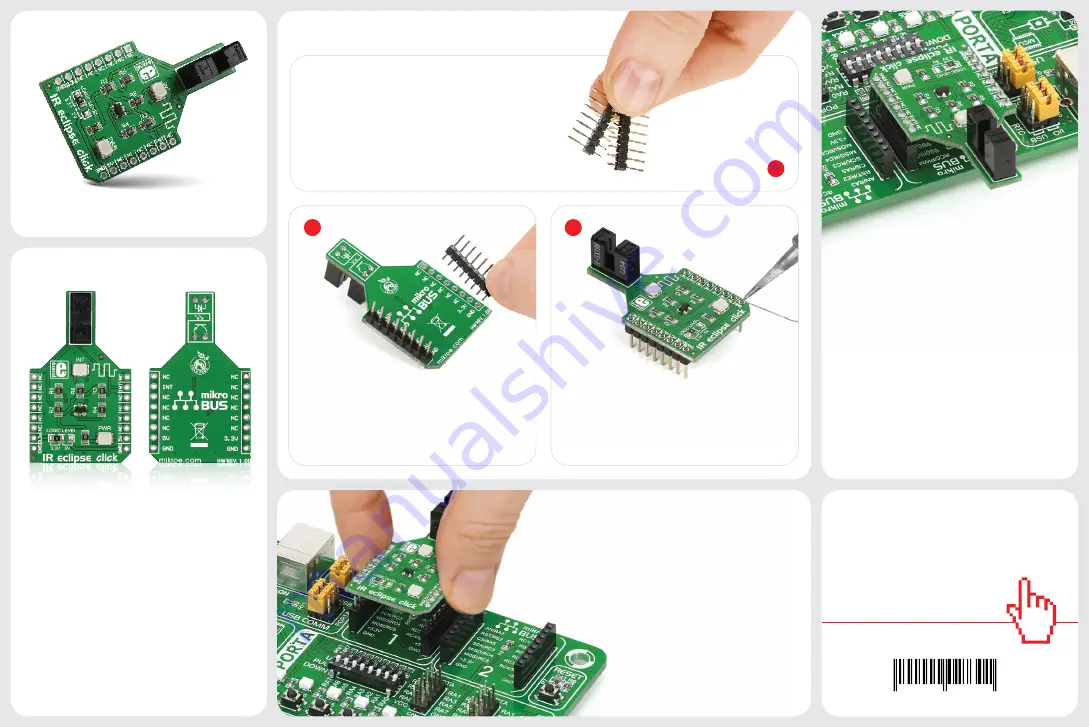

2. Soldering the headers

1. Introduction

3. Plugging the board in

Once you have soldered the headers your

board is ready to be placed into the desired

mikroBUS

™

socket. Make sure to align the

cut in the lower-right part of the board with

the markings on the silkscreen at the

mikroBUS

™

socket. If all the pins

are aligned correctly, push the

board all the way into the socket.

Turn the board upward again. Make sure

to align the headers so that they are

perpendicular to the board, then solder

the pins carefully.

Turn the board upside down so that

the bottom side is facing you upwards.

Place shorter pins of the header into the

appropriate soldering pads.

Before using your click

™

board, make sure

to solder 1x8 male headers to both left

and right side of the board. Two 1x8 male

headers are included with the board in

the package.

4. Essential features

Photo interrupter sensors are typically

used in printers, copiers, vending machines,

for optical limit switches and so on. You

can implement IR eclipse in your design

wherever there’s a need to detect the

position of a moving part, whether you need

to detect if said part is in correct place, or to

infer speed of rotation — as long as its thin

enough to fit in the 3mm-wide slit where

the infrared beam passes through.

1

IR eclipse

click

™

IR eclipse click

™

carries an

EE-SX198

photo

interrupter sensor. This sensor consists of

an infrared transmitter and receiver facing

each other and spaced apart by a 3mm

slit. When the beam from the transmitter

is eclipsed with by placing an object in the

gap (like a piece of paper), the sensor is

activated (indicated by the onboard INT

LED). IR eclipse click

™

communicates with

the target board through the

mikroBUS

™

INT line. It’s designed to work with either

a 3.3V or 5V power supply.