2

3

click

™

BOARD

www.mikroe.com

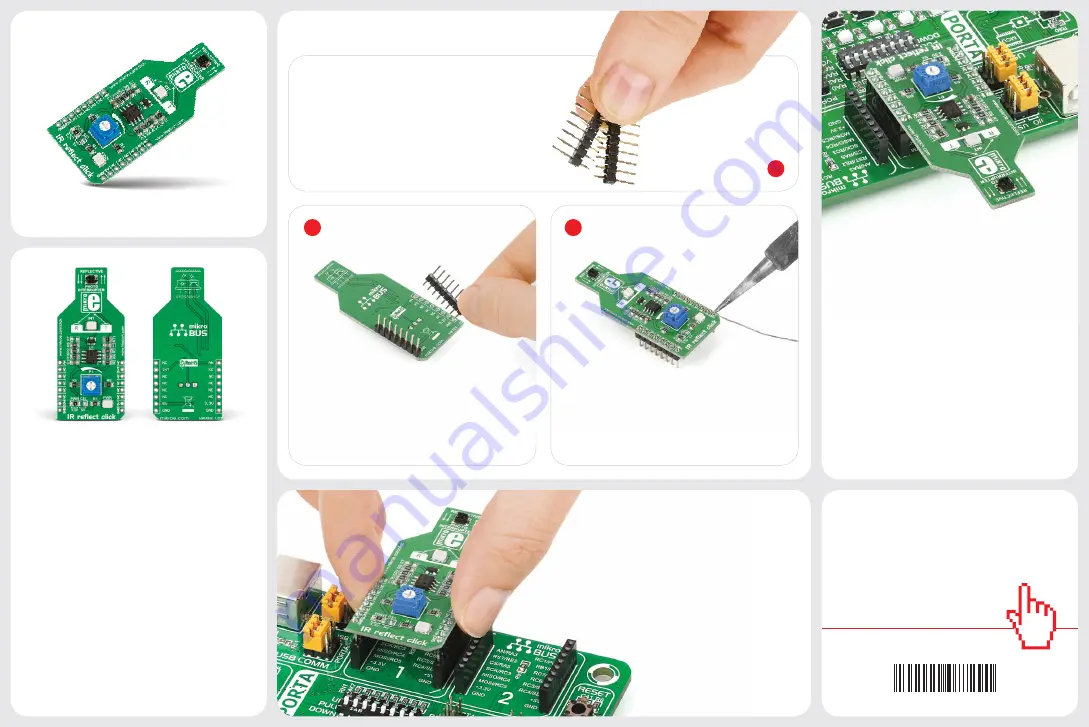

2. Soldering the headers

3. Plugging the board in

Once you have soldered the headers your

board is ready to be placed into the desired

mikroBUS

™

socket. Make sure to align the

cut in the lower-right part of the board with

the markings on the silkscreen at the

mikroBUS

™

socket. If all the

pins are aligned correctly,

push the board all the way

into the socket.

Turn the board upward again. Make sure

to align the headers so that they are

perpendicular to the board, then solder the

pins carefully.

Turn the board upside down so that

the bottom side is facing you upwards.

Place shorter pins of the header into the

appropriate soldering pads.

Before using your click

™

board, make sure

to solder 1x8 male headers to both left and

right side of the board. Two 1x8 male headers

are included with the board in the package.

4. Essential features

These sensors are used to detect an object’s

presence or motion

, such as a piece of paper

passing through a printer. To avoid setting

off false alarms, avoid exposing the sensor

to other sources of infrared light (which

could come from an ordinary incandescent

light bulb). Also, black objects won’t reflect

infrared so the click

™

won’t detect them. On

the other hand, reflective metalic surfaces will

trigger the sensor from a larger range.

1

IR reflect click

™

carries a

GP2S700HCP

reflective photointerrupter

. On this type of

photointerrupter the infrared emitter and

receiver are facing the same direction; the

infrared beam from the emitter gets bounced

back to the receiver when an object is placed

within the detecting range of the sensor

(Optimal Sensing Distance is 3mm). IR reflect

click

™

communicates with the target board

microcontroller through

mikroBUS

™

AN and

INT pins (an onboard potentiometer sets

the Interrupt threshold). It’s designed to use

either a 3.3V (by default) or 5V power supply.

1. Introduction

IR reflect click

™

manual

ver 1.02

0100000077290

IR reflect

click

™