Design: Components and Function

2

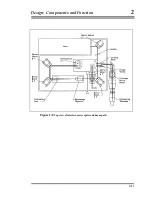

2.5.2.DROPPER CONTROLLER

The dropper controller

uses

three modes to operate the dropping chamber.

These modes are OSC, AUTO, and MANUAL. The operator also controls the

status of these modes and the dropper triggering with the RESET and INIT

switches and the trigger source (INT/EXT) switch. See Chapter 4 for a

detailed discussion of the modes and switches.

The dropper controller can direct the motor in the Dropping Chamber to lift

the cart and test mass to a specified height, to move the cart at a specified

velocity, and to track the test mass during free-fall.

The motor drives the cart/test mass assembly by turning a pulley and

stainless steel drive belt which is attached to the cart. The motor also turns an

optical shaft encoder that provides accurate information to the dropper

controller on the position and velocity of the pulley.

Information on the relative position of the test mass to the cart during free-fall

is provided by a sphere detector system. An LED and a linear detector are

mounted on opposite sides of the cart, and an optical glass sphere is mounted

on the test mass. The sphere focuses a beam of light from the LED onto the

linear detector, indicating the precise location of the center of the sphere

relative to the cart. The dropper controller uses this information to determine

whether to maintain, increase, or decrease current to the motor to achieve the

appropriate relative position of the cart and the test mass. This feedback

system is a conventional analog servo system.

2.5.3.SUPERSPRING CONTROLLER

2-19

The purpose of the electronic and mechanical systems for the Superspring is

to isolate the reference mass from any vertical motion of the instrument in

order to keep the path length of the test beam constant. Three systems

provide coarse and fine adjustment of the spring support structure: a motor

attached to the top of the mainspring, a

linear actuator

coil and magnet

system, and an

aneroid wafer assembly

. A controller circuit board drives the

Summary of Contents for FG5

Page 22: ...Design Components and Function 2 Figure 2 10 The Superspring 2 14 ...

Page 31: ...Design Components and Function 2 Figure 2 13 Rotation Monitor 2 23 ...

Page 32: ......

Page 42: ...How to Set Up and Run the FG5 3 3 10 ...

Page 44: ...How to Set Up and Run the FG5 3 Figure 3 2 V Post 3 12 ...

Page 53: ...How to Set Up and Run the FG5 3 1 Backup the data 2 Shut off computer power 3 21 ...

Page 87: ...Adjustment and Maintenance 4 4 29 ...

Page 91: ...Adjustment and Maintenance 4 4 33 ...

Page 104: ...Troubleshooting 5 5 2 ...

Page 117: ...Troubleshooting 5 5 15 ...

Page 131: ...Checklists and Logs Appendix D 9 3 ...

Page 140: ...Checklists and Logs Appendix D Table 9 6 Replacing Drive Belt 9 12 ...

Page 145: ...Checklists and Logs Appendix D Table 9 10 Replace Linear Bearings 9 17 ...

Page 149: ...Checklists and Logs Appendix D Table 9 13 Replace Shaft Encoder 9 21 ...