11

ATTENTION!

It is extremely important that products used in cleaning ensure maximum cleanliness and

are non-toxic.

Dry the blade thoroughly. Moisture compromises the life of the blade and yield of the

cutting process.

ATTENTION!

Take care when cleaning near the blade, it is extremely sharp. Handle with care because this

may cause accidents. The same attention is paid to any other cutting component of the

equipment.

5.2 Maintenance and Procedures in Case of Breakdowns

The operator must be instructed to perform routine inspections, making minor adjustments,

cleaning and observing signs of breaches that may occur. Examples include: checking for strange

noise; loss of equipment power; the non-execution by the equipment of the service to which it is

proposed; among others. Actions like these are indispensable to ensure a longer equipment life.

ATTENTION!

When servicing (even minor adjustments), always disconnect the equipment from the mains.

It is recommended to carry out preventive maintenance every 6 months, checking and

adjusting clearances, cleaning internal parts, wear and tightening (tensioning) of the motor belt, etc.

When detecting broken or weakened parts, replace with original parts.

By performing preventive maintenance, you eliminate the inconvenience of getting the

equipment stopped when you need it most, reducing the cost of maintenance and reducing the risk of

accidents.

ATTENTION!

Preventive maintenance requires a trained professional or authorized technical assistance.

Make sure that the equipment is disconnected from the mains.

Whenever any item regarding the safety of the equipment (such as cleaning or maintenance) is

removed, reset it and confirm that it is performing its function correctly.

When you experience any malfunction or non-compliance, refer your equipment to the

nearest service center. See technical assistance on our website:

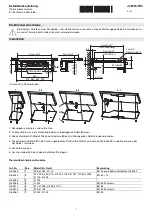

Summary of Contents for BIMG FP 12 Series

Page 1: ...1...

Page 14: ...14 Exploded View...

Page 15: ...15 Exploded View...

Page 18: ...18 Notes...

Page 19: ...19...