30

annunciator, 3 – relay RM 84-2012-35-1012

RELPOL and base GZT80 RELPOL.

12.14

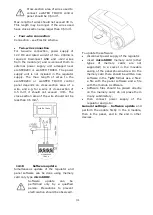

Connection of mixer

When connecting mixer servo,

take due care to prevent boiler

overheating, which may occur

when the flow of boiler water is

limited. You are advised to get

familiar with the position of the

valve

corresponding

to

its

maximum

opening

before

commencement of work so that

you may ensure heat collection

from the boiler at any time it is

required by opening it completely.

The regulator works only with mixing valve

servos equipped with limit switches. Use of

other servos is not allowed. The servos of full

turn time from 30 to 255 s may be used.

Description of mixer connection:

- connect mixer temperature sensor, -

connect mixer pump wiring,

- switch on the regulator and select proper

Mixer support in the service menu

Service settings

Mixer 1 Settings

- enter the proper Valve opening time in (this

time should be indicated on servo rating

plate e.g. 120 s).

- connect power supply to the regulator and

switch on the regulator to start the mixer

pump,

- determine direction of servo closing/

opening. For this purpose, set the selector

located on the housing of the servo to

manual control and find the positions in

which the temperature in mixer circuit is

maximum and minimum (it corresponds to

the setting of the regulator of "100% ON"

and "0% OFF, respectively). Note the

position to verify the connections later,

- disconnect power supply to the regulator,

- connect mixer servo and regulator wiring

according to valve servo manufacturer's

technical documentation. Do not mistake

direction of valve opening with its closing,

- connect regulator power supply,

- check whether wires to mixer closing and

opening are not interchanged. To do this,

enter MENU Manual control and open the

mixer by selecting Mix1 Open = ON. When

opening the servo, the temperature on mixer

sensor should increase. If not, disconnect

regulator power supply and switch the wires.

Note: Other reason may be incorrect

mechanical connection of the valve! – refer

to the documentation of valve manufacturer

and check whether the valve is properly

connected.

12.15

Connecting temperature

limiter STB

When temperature of water in the boiler

exceeds 95°C, power supply of the electric

feeder and the fan is cut off by the safety

temperature limiter. To reset the limiter it is

needed to press the button placed in the side

of the casing, near the power switch.

Pressing of that button is only possible when

temperature of water in the boiler drops.

If the regulator is not factory-equipped with

the safety temperature limiter, the STB

should be connected as an external device.

The STB temperature limiter should be

connected to the 1-2 terminals shown on the

electric scheme. If the safety temperature of

water in the boiler exceeds, the power supply

of the fan and the engine of feeder will be

cut off by the temperature limiter.

Safety temperature limiter should

have nominal operation voltage of

~230V and should follow current

regulations.

Warning: 1-2 terminals are under

dangerous voltage.

12.16

DS input

There is a possibility of connecting the sensor

that detects a door or fuel tank flap opening.

Opening of the DS contact results in

disconnection of the fan and the feeder

power supply. DS connector is under safe

voltage.

12.17

Connecting room panel

The regulator can be equipped with room

panel ecoSTER TOUCH, which can serve as:

- room thermostat,

- boiler control panel,

- alarm signalling device,

- fuel level indicator.

Summary of Contents for ecoMAX860P TOUCH

Page 2: ......

Page 6: ...6...

Page 7: ...INSTRUCTION MANUAL ecoMAX 860P TOUCH...

Page 17: ...INSTALLATION AND SERVICE SETTINGS ecoMAX 860P TOUCH...

Page 43: ......