21

10

Technical data

Power supply

230V~, 50Hz

Current consumption by

the regulator

0,2 A

Max. rated current

6 (6) A

IP rating of the regulator

IP20

Ambient temperature

T50

Ambient temperature

0...50

C

Storage temperature

0...65

C

Relative humidity

5 - 85% without

steam condensation

Temperature measurement

range of sensors CT4

0...100

C

Temperature measurement

range of sensors CT6-P

-35...40

C

Accuracy of temperature

measurement using

sensors CT4 and CT6-P

2

C

Connectors

Screw terminals at

supply voltage side -

2.5mm

2

Screw terminals at

control voltage side -

1.5mm

2

Graphical display with

touch panel

Display 480x272 pix.

Overall dimensions

340x225x60mm

Total weight

1,6 kg

Standards

PN-EN 60730-2-9

PN-EN 60730-1

Software class

A

Pollution degree

2nd pollution degree

11

Storage and transport conditions

The controller cannot be exposed to

immediate effects of atmospheric conditions

i.e. rain or sunrays. Temperature of storage

and transport should be within scope

-15…+65°C.

During transport the controller cannot be

exposed to vibrations bigger than typical for

transport of boilers as well as direct pressure

upon the clamp cover in order to protect the

STB capillary, which is situated inside the

clamp box for the controller version equipped

with STB device.

12

REGULATOR INSTALLATION

12.1

Environmental conditions

Due to fire risk it is forbidden to use the

controller in proximity of explosive gases or

dust. Moreover the controller cannot be used

in conditions of water steam condensation or

be exposed to effects of water.

12.2

Mounting requirements

Regulator should be installed by qualified and

authorized technician with observance of

applicable standards and regulations. The

manufacturer disclaims any liability for

damage caused by non-observance of

instructions specified in this manual. The

regulator is intended to build into other

equipment, and may not be used as a

stand-alone device.

Ambient temperature and temperature of

mounting base should be within the range of

0…+50˚C. The regulator is composed of two

modules: a control panel and an operating

unit, connected with electric wire.

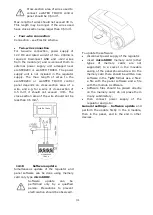

12.3

Module installation

The regulator casing does not provide dust

and water immunity. In order to provide the

protection from these factors the regulator

should be enclosed with a proper casing.

The regulator is to be enclosed – which

means the regulator should be screwed on to

the flat horizontal or vertical surface (e.g.

boiler housing, room wall). To screw on the

regulator use mounting holes and proper

screws. Location and spacing of mounting

holes are shown in the picture below. The

regulator must not be used as a free-

standing device.

After installation make sure that the device is

properly mounted and it is impossible to

detach it from the mounting surface.

Summary of Contents for ecoMAX860P TOUCH

Page 2: ......

Page 6: ...6...

Page 7: ...INSTRUCTION MANUAL ecoMAX 860P TOUCH...

Page 17: ...INSTALLATION AND SERVICE SETTINGS ecoMAX 860P TOUCH...

Page 43: ......