13

Settings for mixer with weather sensor

without

room

thermostat

ecoSTER

TOUCH

Set parameter Mixer weather control to On.

Select weather curve. Using parameter

Curve

translation,

set

preset

room

temperature following the formula:

Preset room temperature = 20°C + heating

curve translation.

In this setup, it is possible to connect a room

thermostat which will equalize the inaccuracy

of selecting heating curve, if the selected

heating curve value is too high. In such case,

it is necessary to set the value of preset

mixer temperature decrease by thermostat,

e.g. at 2°C. After opening of the thermostat

contacts,

the

preset

mixer

circuit

temperature will be decreased, which, if

proper decrease value is selected, will stop

growth of temperature in the heated room.

Settings for mixer with weather sensor

and with room thermostat

Set parameter Mixer weather control to On.

Select weather curve. The room panel

automatically translates the heating curve,

depending on the preset room temperature.

The regulator relates the setting to 20°C,

e.g. for preset room temperature = 22°C,

the regulator will translate the heating curve

by 2°C, for preset room temperature = 18°C,

the regulator will translate the heating curve

by -2°C.

In some cases it may be necessary

to fine-tune the heating curve translation.

In this setup, the ecoSTER TOUCH room

thermostat can:

- decrease the heating cycle temperature by

a constant value when the preset room

temperature is reached. Analogously, as

specified in the previous point (not

recommended), or

- automatically, continuously correct the

heating cycle temperature.

It is not recommended to use both options at

the same time.

Automatic correction of room temperature is

carried out in accordance with the following

formula:

Correction = (Preset room temperature -

measured room temperature) x room

temperature coefficient /10

Example:

Preset temperature in the heated room (set

at ecoSTER TOUCH) = 22°C. Temperature

measured in the room (by ecoSTER TOUCH)

= 20°C. Room temp. factor. = 15.

Preset mixer temperature will be increased

by (22°C - 20°C) x 15/10 = 3°C.

It is necessary to find appropriate value of

the Room temp. factor. The higher the

coefficient, the greater the correction of

preset boiler temperature. If the setting is

“0”, the preset mixer temperature is not

corrected. Note: setting a value of the room

temperature coefficient too high may cause

cyclical fluctuations of the room temperature!

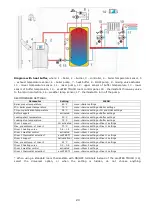

8.17

Weather controlled

Depending on the temperature measured

outside the building, both preset boiler

temperature and temperatures of mixer

circuits can be controlled automatically. If

proper heating curve is selected, the

temperature of the circuits is calculated

automatically, depending on the outdoor

temperature. Thus, if the selected heating

curve is appropriate for the given building,

the room temperature stays more or less the

same, regardless of the temperature outside.

Note: during trial and error selection of

appropriate heating curve, it is necessary to

exclude influence of the room thermostat on

regulator operation (regardless of whether

the room thermostat is connected or not), by

setting the parameter:

Mixer 1 settings

→

Mixer room therm. =

0.

If a room panel ecoSTER TOUCH is

connected, it is also necessary to set the

parameter Room temperature factor = 0.

Guidelines for proper setting of the heating

curve:

floor heating

0,2 -0,6

radiator heating

1,0 - 1,6

boiler

1,8 - 4

Summary of Contents for ecoMAX860P TOUCH

Page 2: ......

Page 6: ...6...

Page 7: ...INSTRUCTION MANUAL ecoMAX 860P TOUCH...

Page 17: ...INSTALLATION AND SERVICE SETTINGS ecoMAX 860P TOUCH...

Page 43: ......