SERVICE AND MAINTENANCE

To assure smooth operation at peak capacity and to

avoid damage to package components, a program of

periodic inspections should be set-up and followed.

The following items are intended as a guide to be

used during inspection and must be combined with

sound refrigeration and electrical practices to assure

trouble free performance.

The liquid line sight glass - moisture indicator on

all circuits must be checked to be sure the glass is

full and clear and the moisture indicator indicates a

“ d r y ” condition. If the indicator shows that a “wet”

condition exists or if bubbles show in the glass even

with a full refrigerant charge, the filter-drier element

must be changed.

Water supplies in some areas may tend to foul the

water cooled condenser to the point where cleaning is

necessary. The fouled condenser wi II be indicated by

an abnormally high condensing pressure and may re-

sult in nusiance trip-outs. To clean the condenser, a

chemical de-scaling solution should be used according

to the manufacturer’s directions.

Systems with remote air cooled condensers require

periodic cleaning of the finned surface of the conden-

ser coil. Cleaning may be accomplished by using a

cold water spray, brushing, vacuuming, or high pres-

sure air. No tools should be used that could damage

the coil tubes or fins.

A lead-l ag switch is provided on all multiple com-

pressor models to permit even distribution of wear on

the compressors. This switch should be turned on an

annual basis.

The compressor oil level must be checked periodi-

cally to be sure the level is at the center of the oil

sight glass. Low oil level may cause inadequate lubri-

cation and oil failure switch trip-out. If the oil level

is low and oil must be added, use Suniso 3G.

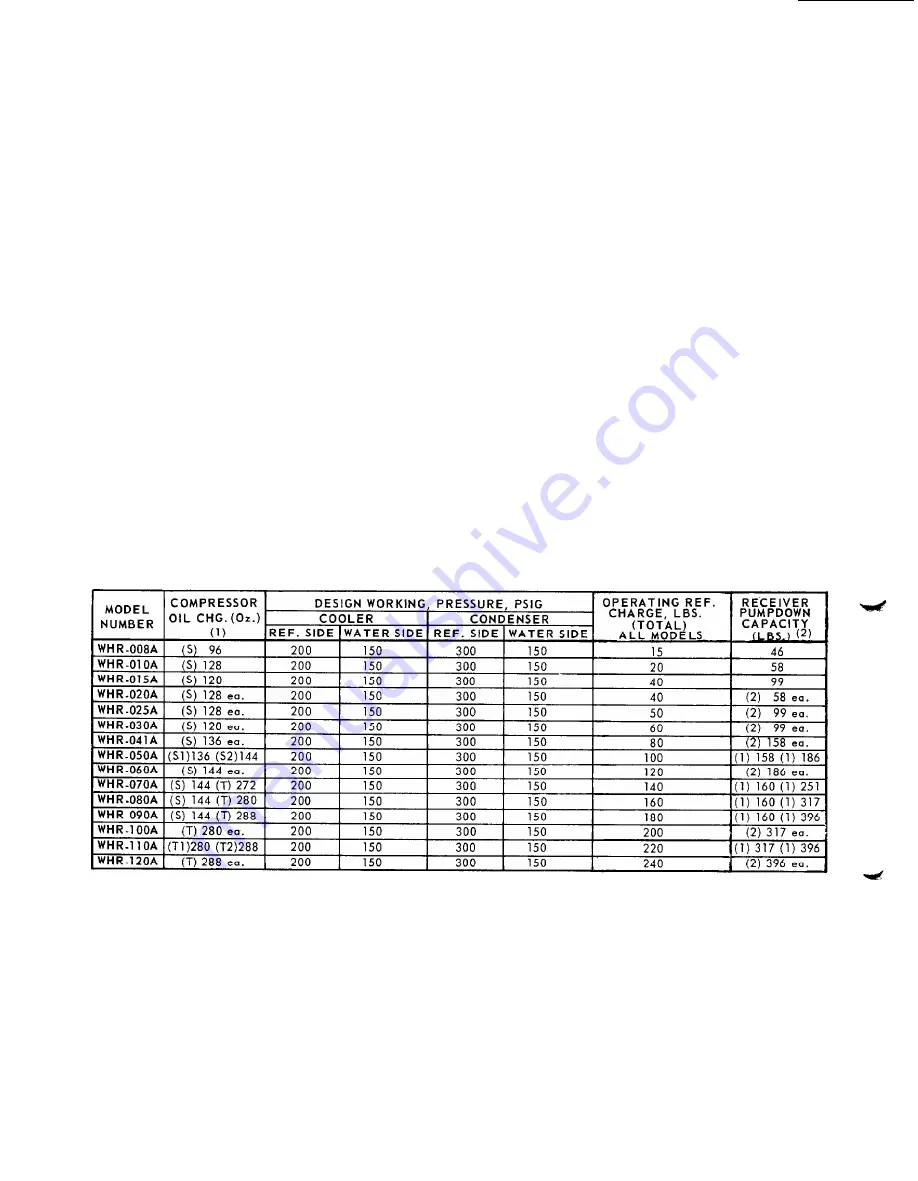

TABLE NO. 9 P H Y S I C A L D A T A

1) COMPRESSOR STYLE: S = SINGLE: T = TANDEM: S1 OR T1 I S L E S S E R H O R S E P O W E R O F T W O C O M P R E S S O R S . .

2) 80% FULL R-22 @100 F.

not

C O N T R O L C E N T E R E L E C T R I C A L S E R V I C E

The electrical control center is relatively easy to ser-

spot can be isolated to a particular section of the

vice. First, ascertain that the problem is actually

somewhere in the control panel. By referring to the

panel. From this point, it is a simple matter to find

and correct the malfunction. A service chart is pro-

schematic wiring diagrams, Diagrams 1 thru 6, Pages

14 thru21 and the Service Chart, Figure 19, the trouble

vided with each Seasonpak when shipped from the fac-

tory.

Page 26