12

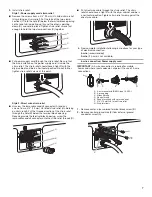

Clamps:

Use clamps to seal all joints.

■

Exhaust vent must not be connected or secured with screws

■

or other fastening devices that extend into interior of vent and

catch lint. Do not use duct tape.

Clamp

Exhaust:

Recommended hood styles.

Acceptable hood style.

4"

(102 mm)

2

½"

(64 mm)

4"

(102 mm)

4"

(102 mm)

B

A

C

A. Louvered hood style

B. Box hood style

C. Angled hood style is acceptable

An exhaust hood should cap the vent to keep rodents and

■

insects from entering the home.

Exhaust hood must be at least 12" (305 mm) from the ground

■

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

Do not use an exhaust hood with a magnetic latch.

■

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

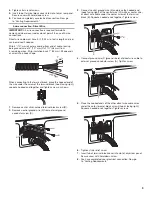

Plan Vent System

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

A

B

B

C

D

E

F

G

H

A. Dryer

E. Clamps

B. Elbow

F. Rigid metal or flexible metal vent

C. Wall

G. Vent length necessary to connect elbows

D. Exhaust hood

H. Exhaust outlet

Standard exhaust installation with rigid metal vent

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

A

B

A. Over-the-top installation (also available

with one offset elbow)

B. Periscope installation

noTE:

The following kits for close clearance alternate

installations are available for purchase. Please see the

“Assistance or Service” section of the Dryer User Instructions.

Over-the-Top Installation:

■

Part Number 4396028

Periscope Installation (For use with dryer vent to wall vent

■

mismatch):

Part Number 4396037 - 0" (0 mm) to 18" (460 mm) mismatch

Part Number 4396011 - 18" (460 mm) to 29" (737 mm)

mismatch

Part Number 4396014 - 29" (737 mm) to 50" (1270 mm)

mismatch

Special provisions for mobile home installations:

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.