6.0 TENSION CONTROL

www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 20 of 68

6.4.3

Tuning Screens

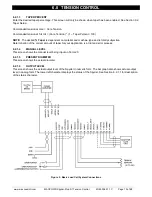

Tuning allows the operator to optimize tuning parameters by using one button to destabilize the system and another

button to stabilize the system. NOTE: The system must be running to perform Tuning. A typical tuning screen looks

like this:

Besides

P

, the parameter being tuned can also be

I

. The number next to this letter is not the value of the

parameter. It is there to show the progress of the tuning. Its values can be between 00 and 99; 00 is displayed

when that parameter is as stable as it can be. To optimize, press

until the system starts to become unstable.

Then press

until stability is again obtained. When finished tuning press

.

Basic set-up of the load cell control system is now complete. See Section 9.0 for optional settings.

There is a table in section 9.6.6 showing default values of proportional, integrator, derivative, error limit and stop

torque ratio for each type control type.

6.5 DIAMETER CALIBRATION

Navigate to the

Cal Diameter

menu and Press

.

This section only applies if diameter is selected to be

Voltage

. For

estimated diameter see section 9.2 Taper setup to calibrate the estimated

diameter.

The diameter calibration is a single point diameter calibration. Only the

large diameter point is calibrated. The lower diameter calibration point is

implied to be 0 volts input equals 0 diameter.

Input a voltage into the diameter input and press the

key on the Present

Diameter screen and enter a diameter that corresponds to the voltage

input. Press the

key to finish diameter calibration.

The Present Diameter screen actively displays the diameter. The Present

Diameter screen is also available from the

Operator

menu.

Summary of Contents for MAGPOWR Spyder-Plus-S1

Page 2: ......