6

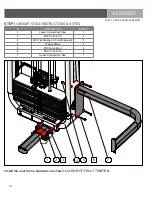

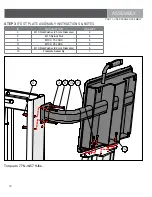

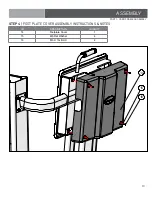

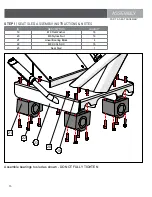

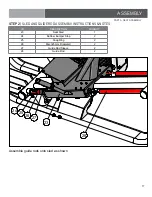

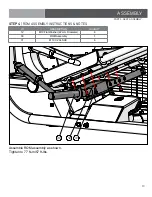

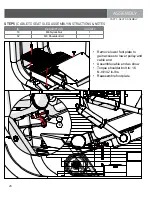

ASSEMBLY

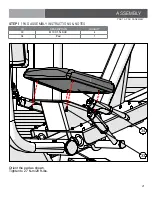

UNPACKING | TOOLS REQUIRED

UNPACKING

Thank you for purchasing a Matrix product. This machine is an EN957-1 and EN957-2 compliant Class S product. Your

Matrix product is inspected before it is packaged. It is shipped in multiple pieces to facilitate the compact packaging of the

machine. Prior to assembly, confirm all the components by matching them with the exploded diagrams. Carefully unpack

the unit from this box and dispose of the packing materials in accordance with your local laws.

CAUTION

The weight of the product is 882 lbs. (400 kg) not including the weight stack. The weight stack for this machine is 400

lbs. (182 kg). To avoid injury to yourself and prevent damage to the frame components, be sure to have proper assistance

removing the frame pieces from this box. Please be sure to install the equipment on a stable base, properly level the

machine and leave at least two feet of clearance to enter and exit the machine. Maximum user weight for this machine is

300 lbs.

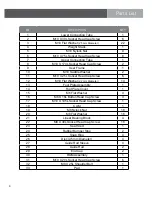

TOOLS REQUIRED FOR ASSEMBLY

3MM L-Shaped Allen Wrench

4MM L-Shaped Allen Wrench

5MM L-Shaped Allen Wrench

6MM L-Shaped Allen Wrench

8MM L-Shaped Allen Wrench

10MM L-Shaped Allen Wrench

Phillips & Standard Screwdrivers

8MM Open-End Wrench

13MM Open-End Wrench

17MM Open-End Wrench.

19MM Open-End Wrench

Adjustable Wrench

Blue Locktite 242 must be used on all fasteners that are not assembled with Nylock Nuts.