DISTRIBUTED BY:

Maruyama U.S., Inc.

3570 Shelby Lane

Denton, Texas 76207

940-383-7400 940-383-7466 (Fax)

Website: www.maruyama-us.com

GUARANTEE

Our products are guaranteed for one year from the purchase

date against defects in material and workmanship. This warranty

is limited to the free replacement of parts recognized as

defective by our service department. The warranty does not

apply for damage due to improper use, disassembly or

modification, nor from normal wear and tear. Warranty does not

apply in case of negligence, imprudence and, improper use of

the equipment. The user may be required to show a copy of

invoice or bill of sale to establish date of purchase..

GENERAL PRECAUTIONS

IMPORTANT: Strictly follow all warnings and

recommendations on the labels for chemical products marked

“dangerous” and “poisonous”. Comply with the application time

and expiration date of each product. Avoid chemical

application during extremely hot periods. Use extreme caution

when spraying near electrical installations.

Never use

alkaline, acids, flammable materials or products which

may a fire hazard. This sprayer is intended to be used

only with herbicides, insecticides and fungicides for

plants. Do not expose chemicals to the sun.

This sprayer

must be safety tested annually by experienced personnel. The

sprayer hose must be the original from the manufacturer.

SAFETY AND HANDLING STANDARDS

Storage.

Place the products in a dedicated, well ventilated and

locked room out of the reach of children and pets. Store the

product in its original packing. Use the same room to store

chemical mixing, preparation and application utensils.

Product Preparation.

Verify that that the chemical and

equipment are not expired and are in good condition. Read and

follow the instructions provided in the product labels and

manuals. Use proper utensils for mixing and preparing and mark

them correctly. After preparation, wash your hands and face.

Dispose properly of empty packages and leftover products.

Safe Procedure.

Use suitable protective equipment. Avoid

contact with the skin and eyes and do not eat, drink or smoke.

Do not apply under windy conditions or against the wind. Avoid

any product drifting into adjacent land and crops. Avoid any drift

into neighboring springs, rivers, streams, lakes, etc.

After Application.

Destroy empty packaging and bottles by

burning or burying them 30 cm deep, away from streams or

wells. Thoroughly clean the treatment machinery. Wash yourself

and your clothes.

Advice in case of poisoning.

Go to the doctor with the

product label or take the affected person to the nearest hospital.

Avoid use of home medicines and, in all cases wash the

affected skin areas with plenty of fresh water.

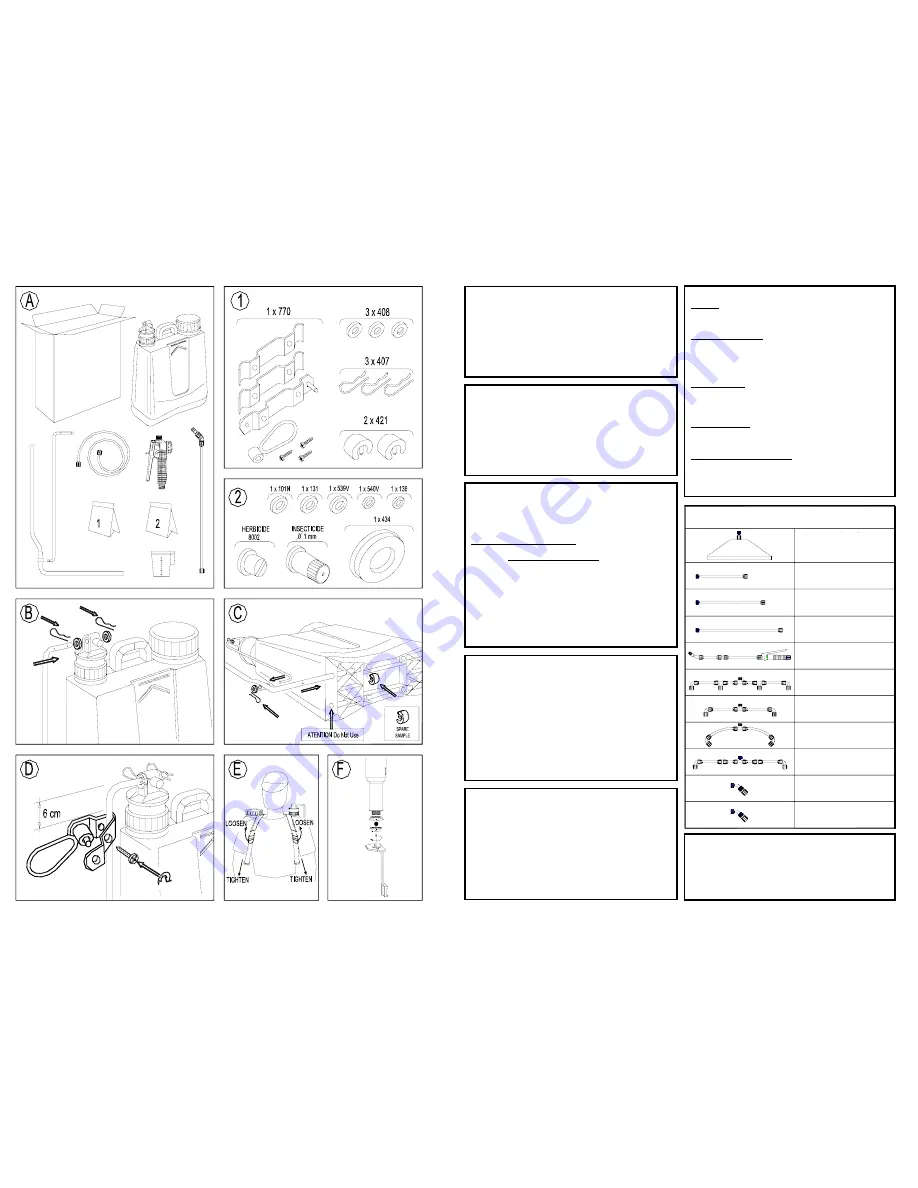

START-UP

Couple the hose

(757)

to the lance

(765)

and to the chamber

(760)

. Unscrew the tank cover without taking out the filter and

pour the liquid to be mixed. Adjust the straps as indicated in

Image

E.

Pump the lever some 8 - 10 times to build pressure.

Press the trigger

(750)

and regulate the nozzle

(123)

rotating it

towards one side and the other to get the desired spray

pattern. Bear in mind that 6 to 8 strokes per minute gives a

flow output of 24 oz./ 0.7 liters to 27 oz./ 0.8 liters/min.

MAINTENANCE & TROUBLESHOOTING

Clean the equipment and internal components, including the

filter at the end of the workday. Clean water and liquid

detergents will assist this process.

NEVER LEAVE THE

SPRAYER PRESSURIZED OR STORE WITH CHEMICALS IN

TANK.

Release pressure and rinse thoroughly.

NOZZLE OBSTRUCTION (123)

Clean nozzle with water

pressure or non metallic instruments taking care not to damage

the orifice.

RETAINER CHANGE (434):

loosen the bolt

(407)

taking care not to miss the washer

(408)

, take out the agitator

horizontally

(425)

, remove the pressure chamber

(760)

. Use the

agitator as in figure

F, f

it the cross on the stirrer blade into the

channels or slots in the valve

(465)

and, unscrew it. Pick up the

ball. Replace the retainer

(434)

with a new one and screw up

again the valve. Do not forget to place the ball inside it. With the

help of the stirrer in the indicated position, tighten the valve

(465)

firmly into the chamber. Proceed to mount the chamber, washer

and the agitator.

PERIODICALLY LUBRICATE THE GASKETS (404S).

INITIAL ASSEMBLY

Image

A

indicates packaging contents.

Drawing

1

indicates the mounting kit contents and 2 is the kit

of spare parts and replacing nozzle. Both are inside the tank.

Place the lever arm on top of the pump and fit it with pieces

(408)

and

(407)

as shown in image

B

. Lay down the tank with

the straps on the bottom and fix the lever to the upper base

hole, by joining in coincidence the bearing with the bottom of

the arm. Fix with pieces (

407)

,

(408)

and

(421)

as per Image

C

. Place the lever shutter as shown in Image

D

.

ACCESSORIES

LIME PREPARATION ELBOW

842627

HERBICIDE ELBOW

842626

DOUBLE EXTENSION NOZZLE

842624

DOUBLE FLEXIBLE NOZZLE

842633

QUADRUPLE FRONT NOZZLE

842618

DOUBLE FIXED NOZZLE

842623

TELESCOPIC LANCE

842625

20”/ 0.5 M EXTENSION

842622

40”/ 1.0 M EXTENSION

842621

60”/1.5 M EXTENSION

842620

RECTANGULAR PROTECTOR BELL

WITH HERBICIDE NOZZLE

842628