Trawl Explorer | V5 | Servicing and Maintenance

5.

Click

Download Depth Programmer

.

The XML file is downloaded in the

Downloads

folder.

6.

Connect the sensor to Mosa2.

7.

From Mosa2, click

Menu

>

Expert Mode

and enter the password

copernic

.

8.

From the tab

General

, click

Depth coefficients

.

9.

Click

Browse

and select the xml file you downloaded.Click

Apply

.

The pressure coefficients are updated.

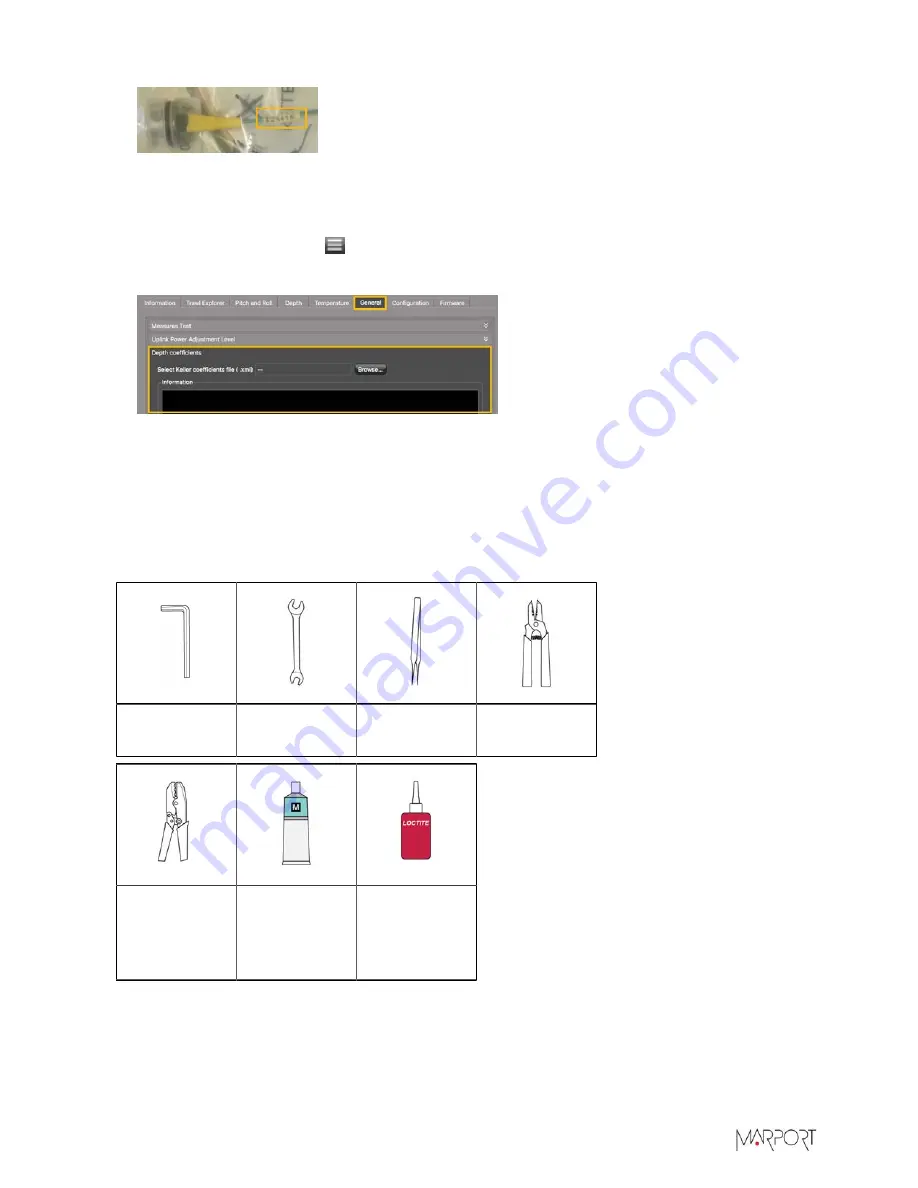

Replacing the Temperature Sensor

Before you begin

For this task you need the following tools:

Allen keys:

1.5 mm, 1/8"

22 mm

wrench

Tweezers

Wire stripper

Crimping tool

O-ring

lubricant

(Molykote 55

o-ring grease)

Loctite 425

About this task

Only qualified Marport technicians can do this task.

74