1

2

3

Replacing valve seat insert

94

Removing valve seat insert

Note:

If the valve seat inserts are replaced, the valve guides must be replaced at the same time as

otherwise exact refacing of the valve seat inserts cannot be guaranteed.

For the above

−

mentioned reasons, the tool for removing and installing the valve guides and valve

seat inserts have been designed in such a way that, when this tool is used, the valve guides and

the valve seat inserts can be replaced only together or only the valve guides alone can be re-

placed.

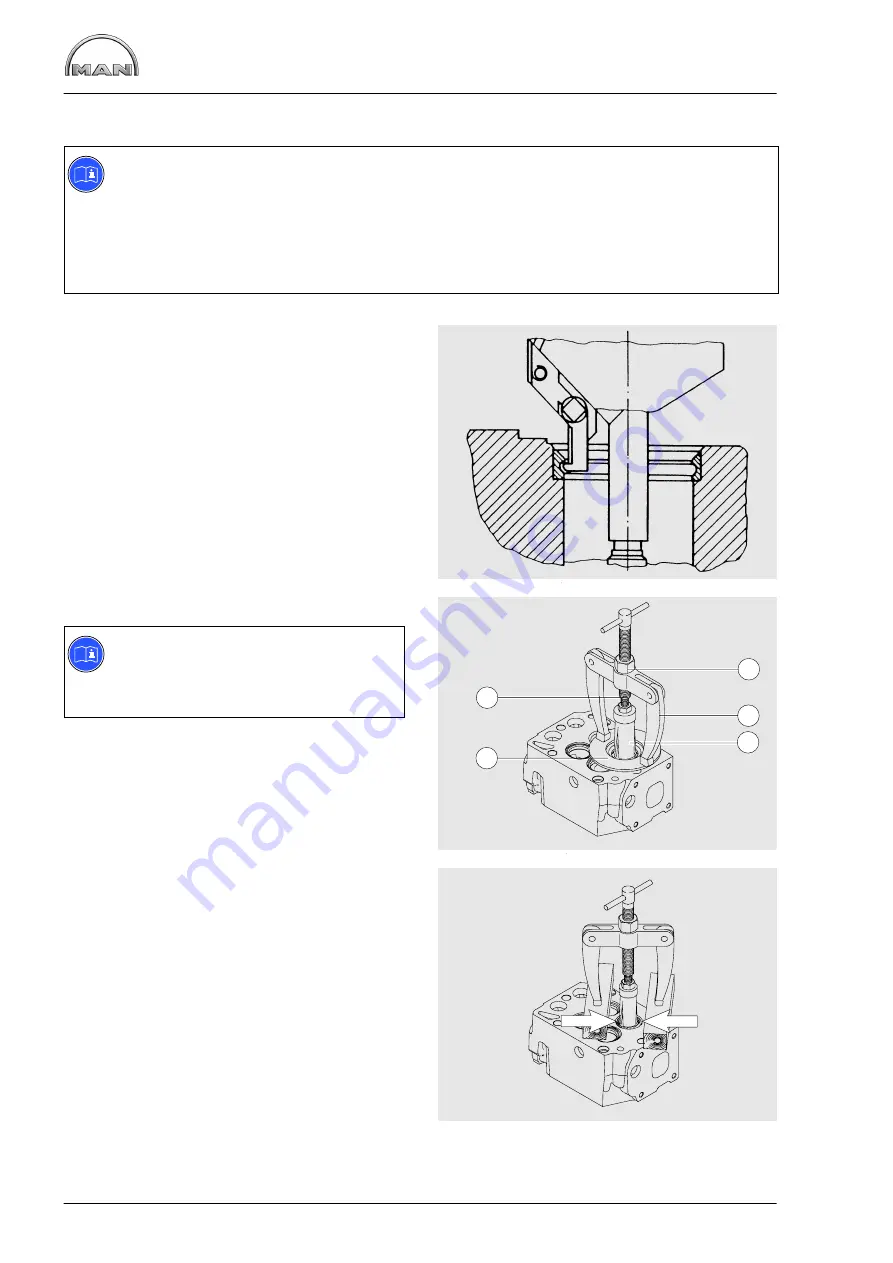

Fig. 1

Use a valve seat machining tool (valve seat turning

tool) to cut a groove approx. 3

−

4 mm wide in the

valve seat insert.

Insert an internal puller into the cut groove and

tighten.

Fig. 2

Note:

To avoid damaging the cylinder head

sealing face, lay disc

Ã

or similar item

under the arms

Á

of the support.

Screw threaded spindle

Ä

into internal puller

Â

,

align arms

Á

of the support and pull out the valve

seat insert by turning nut

À

.

Clean the contact face of the seat insert in the cyl-

inder head.

Fig. 3

If a valve seat machining tool is not available, the

following procedure may be adopted:

D

Apply two short welding beads on the valve

seat (arrow) using an arc welding set

D

Pull out the valve seat insert

D

Clean the contact face of the seat insert in the

cylinder head

3

4

2

5

1

Summary of Contents for D 2842 LE 620

Page 1: ......

Page 2: ......

Page 20: ...Engine views D 2842 LE 620 18 7 1 2 4 3 5 6 7 1 2 4 11 9 10 8...

Page 136: ...134...

Page 137: ...135 Service Data...

Page 163: ...161 Special tools...

Page 164: ...Special tools 162 1 2 3 4 5 6 7 8 9 10 11 11 1 11 2 12 12 1 12 2 13 14...

Page 166: ...Special tools 164 15 1 15 2 15 3 15 4 15 5 1 2 7 15 6 3 4 5 6 15 7...

Page 170: ...Special tools 168 3 1 4 29 5 6 2 29 30 31 32 33 34 35...

Page 172: ...Special tools 170 36 37 38 39 42 40 41 44 2 44 1 44 43 1 43 2 43 3 43 45 46...

Page 178: ...176...

Page 179: ......

Page 180: ......