1

2

3

4

Removing and installing flywheel,

Replacing starter gear ring

77

Removing flywheel

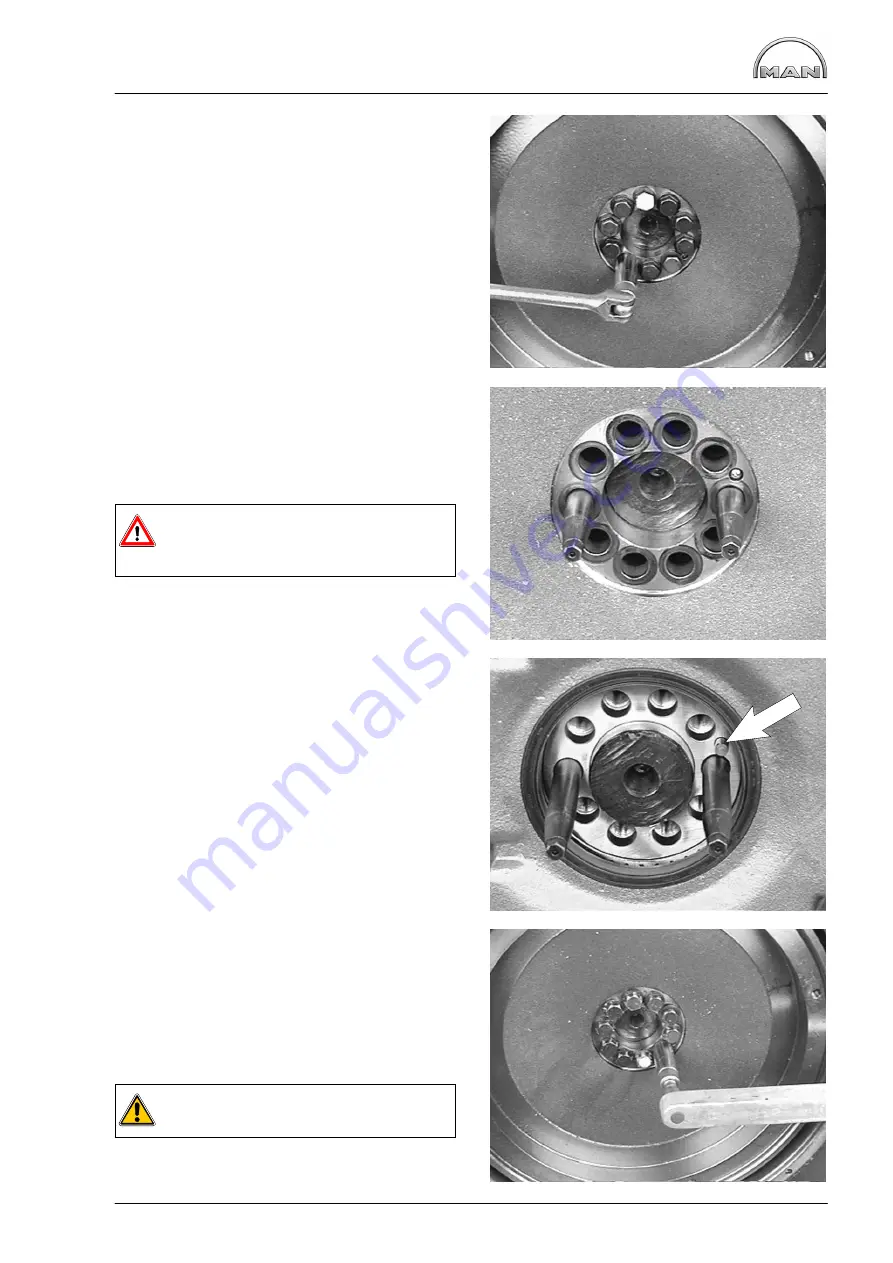

Fig. 1

Release the mounting bolts, securing the engine

against rotating if necessary.

Fig. 2

Unscrew two bolts opposite one another and re-

place with two guide mandrels (special tool).

Remove all the bolts.

Pull off the flywheel with suitable lifting gear.

Danger:

The flywheel is heavy!

Use lifting gear.

Fitting the flywheel

Fig. 3

Insert the guide pins.

Coat the sealing face on the inside of the flywheel

with “Antipor 46” sealing compound.

Place guide mandrels on the flywheel; in doing so,

pay attention to the assignment of the centring pin

(arrow) to the hole in the flywheel.

Push the flywheel on as far as it will go.

Fig. 4

Lightly oil the new mounting bolts (stress bolts),

screw them in and tighten in diagonal sequence to

the specified torque.

Pretightening: 100

−

110 Nm

1st angle tightening: 90

_

2nd angle tightening: 90

_

Caution:

Unblock the crank gear!

D

Install rpm sensor

Summary of Contents for D 2840 LE 301

Page 1: ......

Page 2: ......

Page 16: ...Notes 14...

Page 20: ...Engine views 18 Engine views D 2842 LE 301 9 10 11 12 9 8 6 5 4 3 2 1 13 14 15 16 17 18 6 7 8...

Page 150: ...Notes 148...

Page 151: ...149 Service Data...

Page 179: ...177 Special tools...

Page 180: ...Special tools 178 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 184: ...Special tools 182 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 28 23...

Page 186: ...Special tools 184 30 29 32 31 33...

Page 193: ......

Page 194: ......