Section 13: Microprocessor Computer and Control –Theory of Operation

13-8

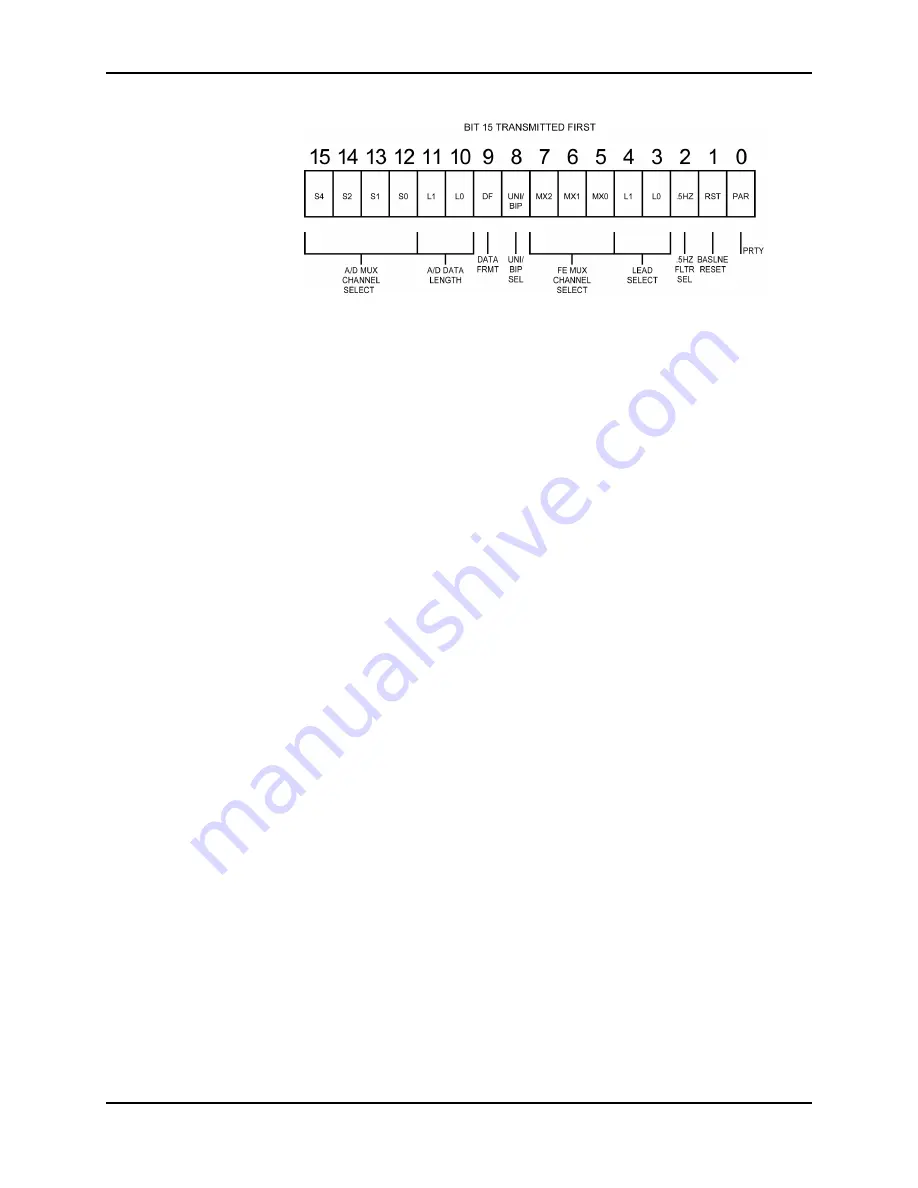

13.5.2 16-Bit Word Transmitted to the A/D Converter and Front End

Figure: 13-5: 16 Bit Word

13.5.3 A/D Converter Receiver Control

The A/D converter is a pipelined converter and transmits the result of the

previous conversion when receiving the next transmission for a conversion . The

previous conversion is transmitted to the SSIO unit’s receiver and the SSIO then

requests a DMA transfer to memory.

13.5.4 SpO

2

INTERFACE

The microprocessor’s asynchronous channel 2 (SIO2) is used to interface to the

SpO

2

unit via opto-isolators. There are two signals, transmit and receive. This

is a UART-type unit and when the SpO

2

transmits, the SIO receives the data and

generates an interrupt to the software. When the software wants to transmit a

byte to the SpO

2

, it transfers data to the SIO transmitter and the SIO unit

automatically transmits it to the SpO

2.

13.5.5 ISOLATED FRONT END POWER SIGNALS

The isolated Front End requires its own power supply and voltages, separate

from the other voltages in the system. The FPGA generates a 100 kHz signal

that connects to an isolation transformer. These signals are enabled/disabled by

a bit in the CS5 control register. These signals are also connected to, and in

synchronization with, the 50 kHz power supply clock. Resetting the Front End

can be accomplished by turning the 100 kHz clock off, then back on again. This

turns the Front End power supply off, then back on.

13.6 RS-232 SERIAL PORT INTERFACE

The RS-232 output serial port uses one of the asynchronous units of the

DUART. It is programmed by the software using CS4 and the A3 address bit set

to 0. This is done in the FPGA and output as DUARTCS0. The eight

programmable registers are internal to the UART channel and are set up for baud

rate, parity, number of bits to transmit, and start and stop bits. This channel also

has an internal register with an extra bit. The circuit uses this bit as the

NURSECALL signal on pin 9 of the RS-232 connector.

Summary of Contents for NELLCOR NPB-4000

Page 66: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 68: ...Section 7 Spare Parts 7 2 Figure 7 1 NPB 4000 C Top Assembly Drawing ...

Page 70: ...Section 7 Spare Parts 7 4 Figure 7 2 NPB 4000 C Front Case Assembly Diagram Sheet 1 of 2 ...

Page 72: ...Section 7 Spare Parts 7 6 Figure 7 3 NPB 4000 C Front Case Assembly Diagram Sheet 2 of 2 ...

Page 74: ...Section 7 Spare Parts 7 8 Figure 7 4 NPB 4000 C Rear Case Assembly Diagram Sheet 1 of 2 ...

Page 76: ...Section 7 Spare Parts 7 10 Figure 7 5 NPB 4000 C Rear Case Assembly Diagram Sheet 2 of 2 ...

Page 78: ...Section 7 Spare Parts 7 12 Figure 7 6 NPB 4000 C Power Supply Heat Sink Assembly Diagram ...

Page 80: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 96: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 114: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 140: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 180: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 192: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 208: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 210: ... THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 211: ...Section 17 Drawings 17 3 Figure 17 1 MP 205 PCB Schematic Sheet 1 of 2 ...

Page 212: ...Section 17 Drawings 17 5 Figure 17 2 MP 205 PCB Schematic Sheet 2 of 2 ...