P 9/ 13

R

epair

[4] TROUBLESHOOTING

Whenever you find any trouble in your machine, refer to this chapter first.

Trouble on Controller can be checked with Tester as follows.

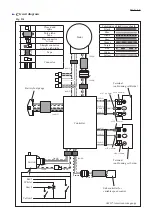

(1) Use a full charged battery which has the star mark. (

Fig. T-1

)

(2) When Housing is disassembled, check the conditions of the electrical parts

(Connectors, Lead wires, Switches, etc.), Rotor, Stator, Gear section, etc.

(3) Do a running test 10 times.

Black test probe

Red test probe

(-) pole

(+) pole

Lock ON

button

Switch lever

1

.

1

Note in Repairin

g

Star mark

Fig.

T -1

Fig.

T -2

Test for recognizing the trouble on FET (Field effect transistor) of Controller

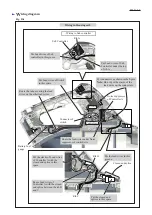

2. After removing the battery from the machine,

lock Switch lever to ON position by pushing

Lock ON button.

1. Set Digital tester (1R402) in the diode mode

( mark on the tester).

3. Connect Black test probe to the plus pole,

Red test probe to minus pole of Terminal.

And, check the value display on the tester.

Note:

Be careful not to connect the probes in reverse.

4. Wait until the reading is stable.

If it reads within

0.9V - 1.3V

,

there is no fault on FET of Controller.

If it reads

0V or 0.4V approx., Controller is

broken

. Replace it with a new one.

Summary of Contents for XBU02

Page 1: ...REPAIR MANUAL XBU02...