P 5/ 13

R

epair

[3] DISASSEMBLY/ASSEEMBLY

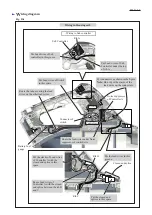

When handling or storing multiple Rotors, be sure to keep a proper distance between Rotors as shown in

Fig. 6

because Rotor has a strong magnetic force.

Failure to follow this instruction could result in:

• Finger injury caused by pinching between Rotors

• Magnetic loss of Rotors or damage on the magnet portion of Rotor (

Fig. 7

)

Fig. 6

Fig. 7

[3] -1. Fan 110, Rotor (cont.)

Caution for Handling of Rotor

* Magnetic loss of Rotors

* Damage on the magnet portion of Rotor

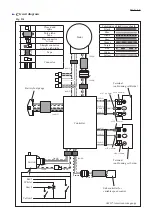

(1) Assemble Ball bearings 626DDW/ 698LLU to Rotor. (

Fig. 5

)

(2) Assemble Motor housing cover to Rotor. And assemble them to Motor housing. (

Fig. 8

)

ASSEMBLING

Fig. 8

Rotor

Rotor

Stator

1R032

1R028

Motor housing

1. Set Rotor onto 1R032.

Put Motor housing cover onto Rotor.

Press-fit Motor housing cover using 1R028

and Arbor press.

Motor housing cover

Motor housing cover

and Rotor

Motor housing

Motor housing cover

2. Assemble Rotor and Motor housing cover

to Motor housing.

Note:

Take care that your fingers are not pinched between

Motor housing cover and Motor housing.

1R247

3. Press-fit Motor housing cover and Rotor to Motor

housing using 1R247 and Arbor press.

Summary of Contents for XBU02

Page 1: ...REPAIR MANUAL XBU02...