GB

16

29. DO NOT STO P COMPRESSOR BY PULLING OUT THE

PLUG

Use the “AUTO/OFF” knob of pressure switc h.

30. USE ONLY RECOMMENDED AIR HANDLING PARTS

ACCEPT ABLE FOR PRESSURE NOT L ESS TH AN 125 PSI

(8.6 B AR)

Risk of bursti ng. Use onl y recommended air handling parts

acceptabl e f or pressur es not less than 125 psi ( 8.6 bar).

REPLACEMENT PARTS

When s ervicing us e onl y identic al replac ement parts.Repairs

shoul d be conducted onl y by authorized s ervic e center.

SAFETY

GROUNDING INSTRUCTIONS

This compress or shoul d be grounded while in us e to prot ect the

operator from elec tric shoc k.The compress or is equipped with a

three-conductor cord and three-prong grounding t ype pl ug to fit the

proper grounding type receptacle. The green (or green and yellow)

conductor in the cord is t he grounding wire. Never connect the

green (or green and yellow) wire to a li ve termi nal. If your units is

for use on less than 150 volts, it has a plug that looks like t hat

shown i n s ketch (A) i n figure on the right. An adapter, see s ketches

(B) and (C), is availabl e for connecti ng sketch (A) type pl ugs to

two- prong receptacles. T he green-color ed rigid ear, lug, or the like

extending from t he adapt er mus t be connected t o a permanent

ground, s uch as a properly grounded outlet box.

NOTE:

the

grounding adapt or, sketch (C), is prohibited in Canada by

Canadian El ectrical Code Part. 1. Theref ore, the instruc tions f or its

use are not applicable in Canada.

EXTENSION CORD

Use onl y three-ext ension cords t hat have three-prong grounding

type plugs and three-pole receptables t hat acc ept the compr essor’s

plug. Replac e or repair damaged c ord. Make sure your extension

cord is in good c ondition. When usi ng an extension cord, be sur e to

use one heavy enough to carr y the current your product will draw.

An undersized cord will caus e a drop in line volt age resulting in

loss of power and overheating. Table s hows the correct size to use

depending on c ord lenght and name plat e ampere rating. If in

doubt, use the next heavier gage. T he smaller the gage number,

the heavier the c ord.

Tab.1 SECTION VALID FOR A MAX LENGHT OF 20 mt single-

phas e

HP kW

220/230V

50 Hz (mm²)

110/120V

60 Hz (mm²)

0.75 0.65 1.5 2.5

1 0.75 1.5 2.5

1.5 1.1 2.5 4

2 1.5 2.5

4

-6

3 2.2 4 /

W ARNING

Avoid electrical s hoc k haz ard. Never us e t his compress or wit h a

damaged or frayed electrical c ord or ext ensi on cor d. Ins pect all

electrical cords regularly. Never use i n near wat er or in any

environment where electric shoc k is possible

SAVE THIS INSTRUCTION AND MAKE THEM

AVAILABLE OTHER USERS OF THIS TOOL!

OPERAT ION AND MAINTEN ANCE NOTE:

The inf ormation

cont ained in this Instr uction Manual is designed to assist you in the

safe operation and maintenance of the compress or. Some

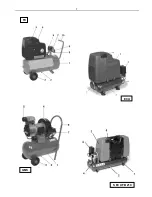

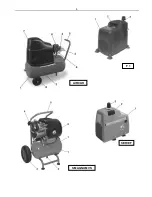

illustrations in this Instruc tion Manual may show details or

attac hments that differ from those on your own c ompressor.

INSTALL ATION

After havi ng removed t he compress or from its

pac king (fig. 1) and having chec ked its perfec t integrit y, making

sure that it has not been damaged during transport, proceed as

follows .

COMPRESSOR W ITH TANK (FIG.20)

Fit the wheels and the rubbers on the tanks where t hese have not

been fitt ed, f ollowi ng the instr uctions provided in fig. 2. Also fit the

air filter (fig. 2B) in c ompressors in which t his has not been fi tted.

COMPRESSOR W ITHOUT TANK (FIG.21)

Fit the suc tion cups underneat h t he base of the unit as indic ated in

fi g.2A. Position the compress or on a fl at s urface or one with an

inclination of 10° at the most (fig. 3), in a well-ventilated area away

from at mos pheric agents and not in explosi ve areas . If the surface

is sloping and smooth, make sure that the c ompressor does not

move while running, ot herwis e bloc k t he wheels with two wedges.

If t he s urfac e c onsists of a s helf or t he ledge of a stand, make sure

that it may not f all off by sec uring it appropriat ely. The compress or

must be positioned at l east 50 c m away from any walls to ensure

its ideal ventilation and eff ecti ve c ooling. (fig. 4).

THIS COMPRESSOR RUNS W ITHOUT OIL (4A)

OPERAT IONAL INSTRUCTIONS

-

Transport the compr essor in the correct manner wit hout tipping it or

lifting it with hooks or ropes . (fig. 5 - 6)

ELECTRICAL CONNECTION

The

single-phase compressors

are supplied c omplet e with an electrical c able and two-pol e + earth

power plug. The c ompressor must be connec ted t o a power s oc ket

provided with eart h connection. (fig. 7)

W ARNING:

The eart h connec tion must be ac hieved acc ording to the industrial

safet y s tandar ds (EN 60204). The plug of t he power s upply c able

must not be used as a s witch but must be plugged into a power

socket t hat is controlled by a suitable differ ential s witc h (magneto

thermal s witch).

STARTING

Make sure that the mai ns voltage corresponds to t hat indicated on

the el ectrical dat a nameplat e (fig. 8), the admit ted tolerance range

must remain withi n ± 5%.

COMPRESSOR W ITH TANK (Fig. 20):

Turn or press, depending

on the t ype of press ure s witch fitt ed on t he equipment, the knob

situat ed in the upper part to «0» (fig. 9). Put t he pl ug in the power

socket (fi g. 7) and turn t he knob to «I». Attac h the rubber hos e or

the spiral t ype hose to t he appr opriat e fi tting situated near the

pressure s witch (fig.25). The c ompressor runs in a c omplet ely

aut omatic manner and is c ontrolled by the press ure s witch t hat

stops it when t he pressur e inside t he tank reac hes the maximum

pressure and s tarts it again when the press ure falls bac k down to

the minimum l evel. The diff erenc e in press ure is usually 2 bar (29

psi) roughly bet ween t he maximum and mi nimum value. I.e.: the

compressor st ops when it reac hes 8 bar (116 psi) ( max. running

pressure) and is aut omaticall y re-start ed when the press ure inside

the tank f alls t o 6 bar (87 psi). Aft er having connected the

compressor t o the el ectrical power suppl y line, l oad to the

maxi mum pressure and chec k t he c orrect efficienc y of the

mac hine.

COMPRESSOR W ITHOUT TANK (Fig. 21)

: Put t he plug in the

power soc ket (fig. 7). Press the starting push butt on situated at the

side of the compressor (fig. 9A). T his t ype of compress or is

provided wit h a devic e that automaticall y controls the maximum

wor king pressure even if t he us er is not using compressed air.The

compressor aut omaticall y r eleas es t he exc ess air from a val ve

situat ed on t he head. The c ompressor does not st op automatic ally.

Use the ON/OFF pus h butt on to s top the c ompressor. Att ach the

rubber hos e or the spiral t ype hos e t o the appropriate fi tting

situat ed at t he top of the c ompressor, near the gear mot or (fig. 25).

NOTE:

The head/c ylinder/ deli ver y hos e unit situated beneat h the

panelling may r each high temperat ures t heref ore be c areful when

wor king near these components and do not touch t hem to avoid

getting burned (fig. 10).

Summary of Contents for AC1300

Page 4: ...4 ...

Page 5: ...5 ...

Page 6: ...6 ...

Page 7: ...7 FX ECU GMS S ECU FB 210 ...

Page 8: ...8 F 1 AIRCLIK SERIE F S MAGNUM VS ...

Page 54: ...Cod 734 637 0000 02 2008 ...