11. Carefully examine all seals and gaskets, replacing if necessary. Look

for any evidence of leaks or corrosion and if found determine and

rectify the cause.

12. Reassemble in reverse order.

13. Complete the relevant Service Interval Record section of the

Benchmark Commissioning Checklist at the rear of this publication

and then hand it back to the user.

9.2.2

Checking the water pressure

In order for the boiler to operate correctly, the pressure of the water in the

heating circuit must be between 1.0 and 1.5 bar. Restore the water

pressure if necessary.

9.2.3

Checking the expansion vessel

Check the expansion vessel and recharge or replace it if necessary.

Check its pre-charge every year and restore the pressure to 1 bar if

necessary.

9.2.4

Checking the automatic air vent

Check that the boiler pump venting valve is working. In the event of a leak,

replace the valve.

9.2.5

Checking the burner and cleaning the heat exchanger

1. Isolate the boiler from the gas & electrical supplies.

2. Remove the front panel.

3. Remove the silencer.

4. Disconnect the spark electrode lead and earth wire from the

detection / spark electrode.

5. Remove the clip securing the gas feed pipe to the fan. Disconnect the

pipe.

6. Completely remove the combustion chamber / burner door assembly

by unscrewing the four M6 nuts and drawing it forwards to disengage

it from the heat exchanger..

7. Check that the detection/spark electrode is not worn. Replace the

electrode if necessary.

8. Check the condition of the burner, the gasket and the insulation board.

9. Any loose deposits in the heat exchanger should be removed using a

vacuum cleaner.

10. A brush with plastic bristles can be used to dislodge any stubborn

deposits, which should then also be removed by vacuum.

11. Do not use any chemicals to clean the heat exchanger.

12. The burner does not require any maintenance as it is self-cleaning.

Check that there are no cracks and/or other damage on the surface of

the burner. If the burner is damaged, replace it.

13. Reassemble in reverse order.

Fig.45

PN-0000382

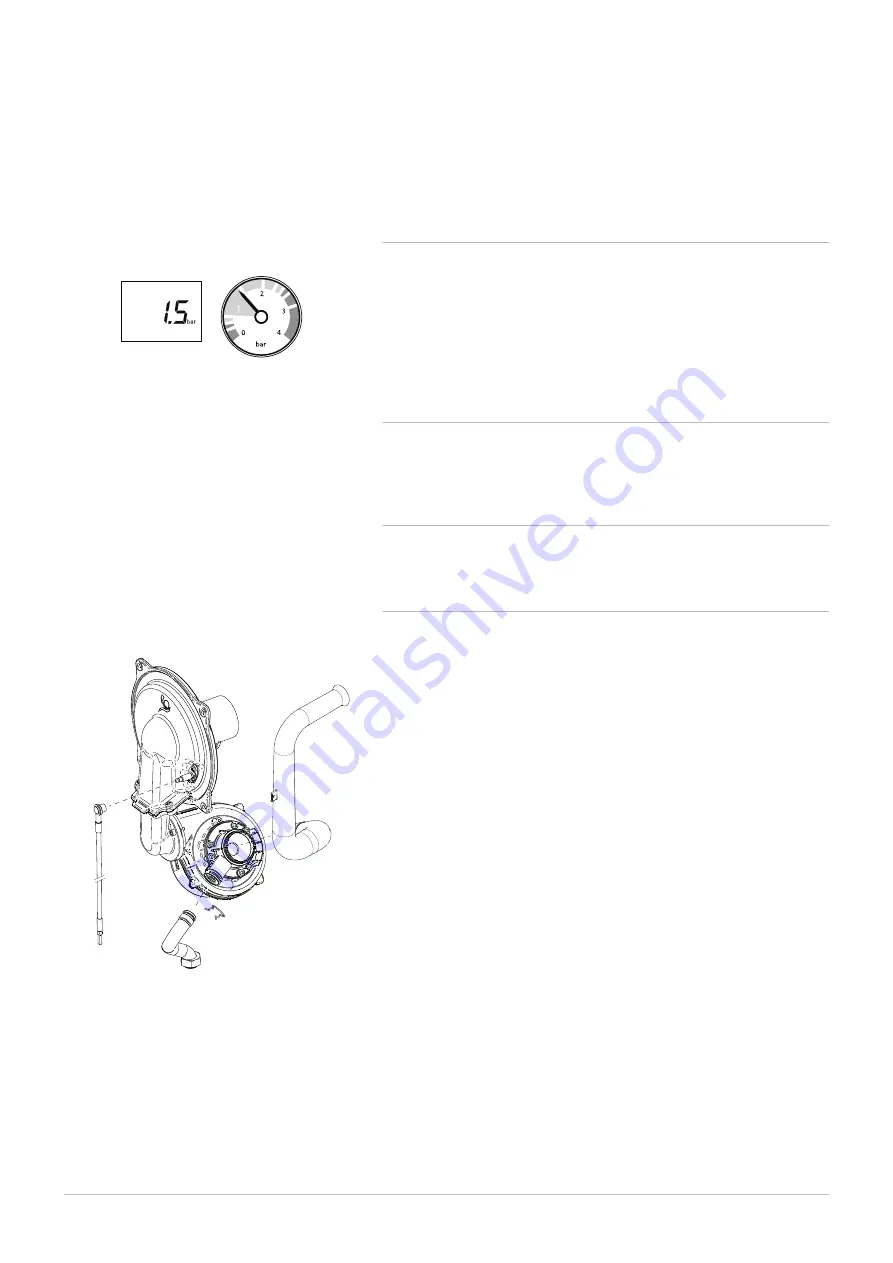

Fig.46

Remove burner / door assembly

PN-0000394

9 Maintenance

50