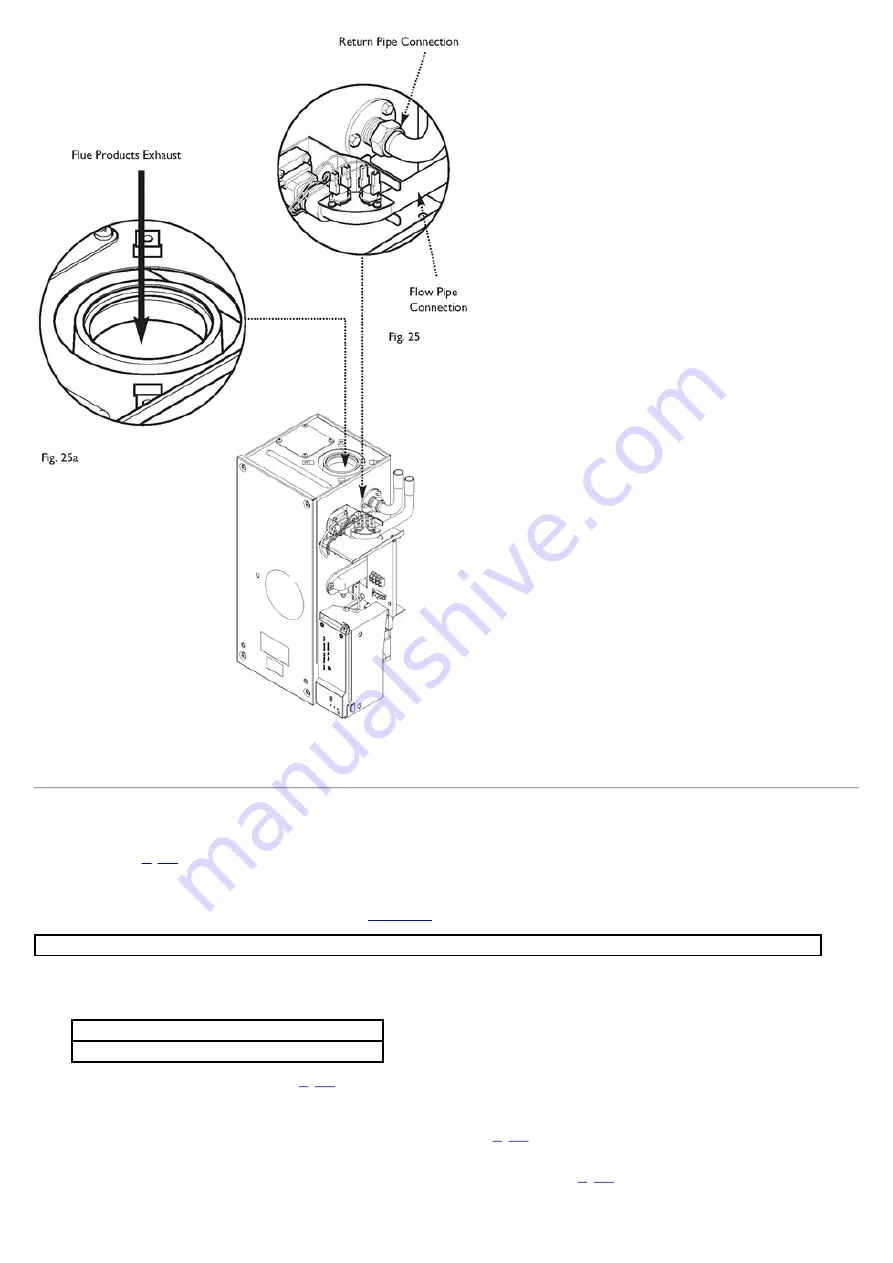

Fig. 25 & Fig. 25a

page 33

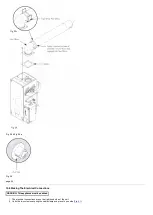

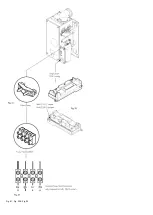

10.6 Making the Gas Connection

1. Connect the gas supply to the G

1

/

2

(

1

/

2

in BSPT Internal) gas tap. This is located on the lower right side of the boiler, access by hinging down the PCB

housing (see

10.7 Fitting The Flue

Before fitting the flue, check the condensate drain integrity (see

).

IMPORTANT: The flue should always be installed with at least 1.5° fall from terminal to elbow, to allow condensate to run back to the boiler.

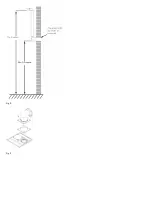

HORIZONTAL FLUE

1. The standard flue is suitable for lengths 270mm minimum to 800mm maximum (measured from the edge of the flue elbow outlet).

Rear Flue:

maximum wall thickness - 630mm

Side Flue:

maximum wall thickness - 565mm (left or right)

2.

For rear exit

- measure the wall thickness (

) and to this dimension add 181mm.

This dimension to be known as (X).

i.e. (X) = wall thi 181

3. Take the flue and mark off (X) from the terminal end as indicated in the diagram (

Check your dimensions.

The flue tubes are fixed together. Cut through both tubes whilst resting the flue on the semi-circular packing pieces. Deburr both tube ends.

4.

For side exit

- measure the distance from the edge of the wall plate to the inner face of the wall (

) and to this dimension add the wall thickness

+ 250mm.

Summary of Contents for Main Heat 12

Page 8: ...Fig 3 Fig 4 Fig 5 Fig 6...

Page 38: ...Example 1 Example 2 Example 3...

Page 40: ...Fig E Fig F...

Page 51: ...Fig 31 Fig 32 Fig 33...

Page 55: ...Fig 35 Fig 36 page 39 12 2 Checking the Combustion 1 Follow the flow chart opposite...

Page 56: ......

Page 63: ...Fig 45 Fig 46...

Page 66: ......

Page 69: ...Fig 55 Fig 56 Fig 57 Fig 58...

Page 72: ...page 52...

Page 74: ...page 54...

Page 75: ...DRY FIRE...

Page 76: ...page 55 IGNITION LOCKOUT...

Page 77: ...page 56 OVERHEAT LOCKOUT...

Page 78: ...page 57 FAN LOCKOUT NOTE The fan is supplied with 325 Vdc...

Page 80: ...warranty This does not affect the customer s statutory rights page 62...

Page 82: ...page 63...