32

BA322301-en

Pos: 121 /Papierkorb/Überschriften/Überschrift 1: Instandhaltung @ 11\mod_1231318736629_75.docx @ 289550 @ 1 @ 1

6

Maintenance

Pos: 122 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: GEFAHR - Hauptschalter aus bei Instandhaltung_12pt @ 54\mod_1534925207098_75.docx @ 3081971 @ @ 1

DANGER

Risk of death or severe personal injury by electric shock

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Pos: 123 /Papierkorb/Überschriften/Überschrift 1.1: Jährliche Überprüfung @ 6\mod_1174482245718_75.docx @ 76817 @ 2 @ 1

6.1

Annual Inspection

Pos: 124 /Produktfamilien/Alle Geräte/Inhalte/Info!/Inhalt: Info - Jährliche Überprüfung_12pt @ 25\mod_1324460481075_75.docx @ 1139412 @ @ 1

•

The maintenance interval prescribed by the manufacturer is 12 (twelve) months.

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

•

Maintenance work shall be done only by authorized and trained service techni-

cians provided by the manufacturer, licensed dealers or service partners.

•

In case of non-compliance the manufacturer's warranty becomes void.

Pos: 125 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Info!/Inhalt: Info - DGUV Regel 100-500 / DGUV Grundsatz 308-003_12pt @ 47\mod_1483611185270_75.docx @ 2804763 @ @ 1

Pos: 126 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/I/Überschrift 1.1: Instandhaltungsplan @ 11\mod_1231318919401_75.docx @ 289622 @ 2 @ 1

6.2

Maintenance Schedule

Pos: 127 /Produktfamilien/Hebetechnik/- Archiv -/32 Stempel-Hebebühnen/0001 Stempel-Hebebühnen Alle/Inhalt/Inhalt: Instandhaltungsplan Stempel-HBZ_12pt @ 26\mod_1326273650740_75.docx @ 1151111 @ @ 1

Interval

Maintenance items

Procedure

3 months

Hydraulic system

Check fluid level, top up if necessary.

Check hydraulic system for leakage.

Check power unit for unusual noise dur-

ing operation. Check fastening screws

for tight fit.

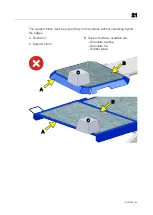

Support discs

Check threads for smooth running.

Flat head supports

Check extensions for smooth running,

grease as required.

6 months

Hydraulic fluid

Check fluid for contamination and age-

ing, replace if necessary.

12 months

General inspection

Check all components for damage.

6 years

Pressure hoses

Replace all pressure hoses.

Pos: 128 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1