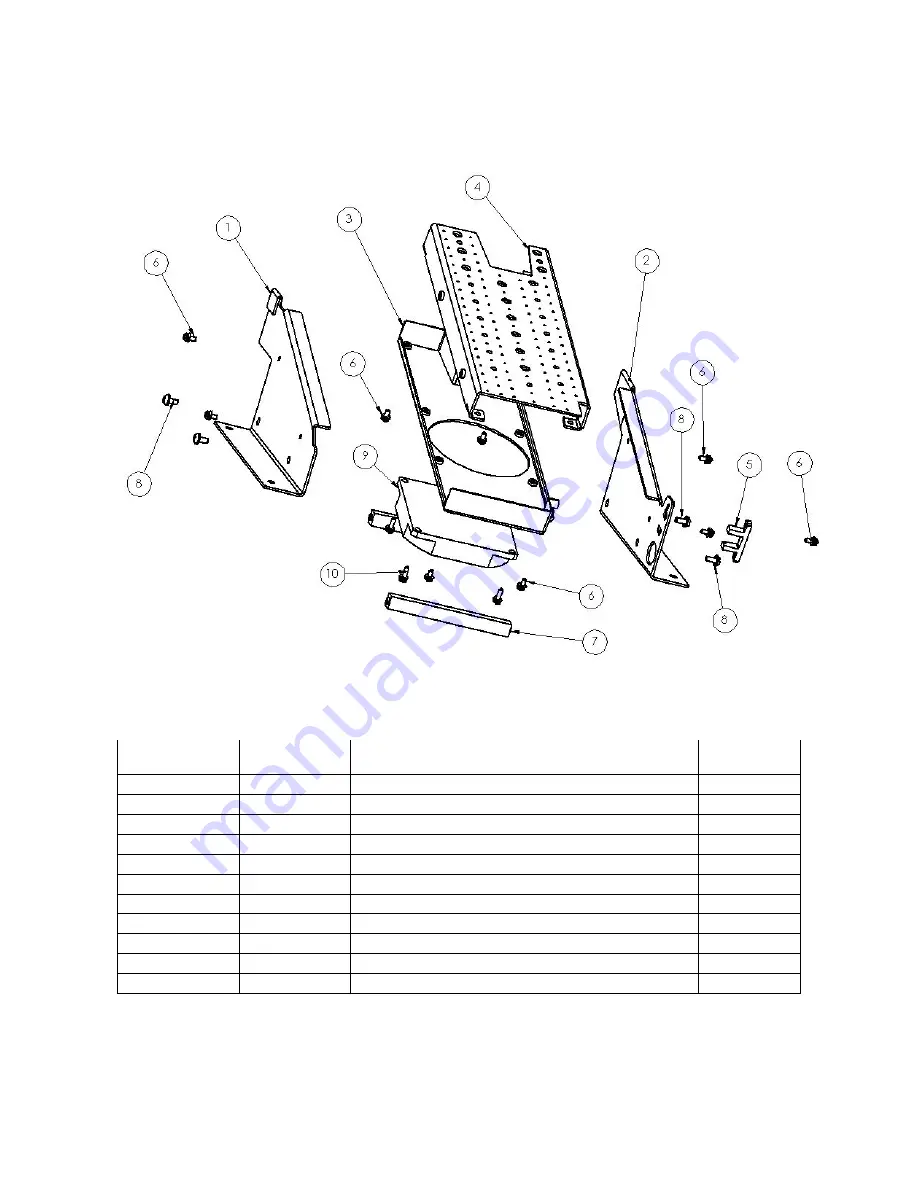

Section 5: Parts Catalog

115

Eject Card Slide

Assembly

Index Part

Number

Description

Quantity

33070462

EJECT SLIDE ASSEMBLY

5-1

33070451

SLIDER LEFT WALL 8.955L

1

5-2

33070452

SLIDER RIGHT SIDE

1

5-3

33070502

FAN MOUNT, EJECT SLIDE

1

5-4

33070443

CARD EXIT SLIDE

1

5-5

33070466

EJECT BIN SEN/EXIT FANS PATCH 2 CABLE

1

5-6

46500027

SCREW SEMS CONE WASH 4-40 X 1/4

4

5-7

33070467

SPACER,SLIDE EXIT 3.31L

1

5-8

46500039

SCREW,SEMS CONE WASH,6-32 X 5/16

2

5-9

66300013

FAN-DC24V 6W 80MM X 80MM X 15MM

1

5-10

46500055

SCREW SEMS CONE WASHER 4-40 X 3/8

4

Summary of Contents for EXPRESSCARD 1000

Page 2: ......

Page 9: ...ExpressCard 1000 Hardware Service Manual 2...

Page 13: ...ExpressCard 1000 Hardware Service Manual 6...

Page 23: ...ExpressCard 1000 Service Manual 16 5 Then select the Calibrate tab 6 Now select Sensors...

Page 27: ...ExpressCard 1000 Service Manual 20 Main Menu screen Password screen...

Page 63: ...ExpressCard 1000 Service Manual 56...

Page 87: ...ExpressCard 1000 Service Manual 80...

Page 93: ...ExpressCard 1000 Service Manual 86...

Page 95: ...ExpressCard 1000 Service Manual 88 5 1 Covers Assembly...

Page 103: ...ExpressCard 1000 Service Manual 96 5 2 Chassis Assembly...

Page 114: ...Section 5 Parts Catalog 107 5 4 X Y Transport Assembly...

Page 121: ...ExpressCard 1000 Service Manual 114 5 5 Exit Transport Assembly...

Page 131: ...ExpressCard 1000 Service Manual 124...

Page 135: ...ExpressCard 1000 Hardware Service Manual 128...

Page 136: ...Section 6 Cabling Diagram Index 129...

Page 137: ...ExpressCard 1000 Hardware Service Manual 130...

Page 138: ...Section 6 Cabling Diagram Index 131...

Page 139: ...ExpressCard 1000 Hardware Service Manual 132...

Page 140: ...Section 6 Cabling Diagram Index 133...

Page 141: ...ExpressCard 1000 Hardware Service Manual 134...

Page 142: ...Section 6 Cabling Diagram Index 135...

Page 143: ...ExpressCard 1000 Hardware Service Manual 136...

Page 144: ...Section 6 Cabling Diagram Index 137...

Page 145: ...ExpressCard 1000 Hardware Service Manual 138...

Page 146: ...Section 6 Cabling Diagram Index 139...

Page 147: ...ExpressCard 1000 Hardware Service Manual 140...

Page 148: ...Section 6 Cabling Diagram Index 141...

Page 149: ...ExpressCard 1000 Hardware Service Manual 142...

Page 150: ...Section 6 Cabling Diagram Index 143...

Page 151: ...ExpressCard 1000 Hardware Service Manual 144...

Page 152: ...Section 6 Cabling Diagram Index 145...

Page 153: ...ExpressCard 1000 Hardware Service Manual 146...

Page 154: ...Section 6 Cabling Diagram Index 147...

Page 155: ...ExpressCard 1000 Hardware Service Manual 148...

Page 156: ...Section 6 Cabling Diagram Index 149...

Page 157: ...ExpressCard 1000 Hardware Service Manual 150...

Page 158: ...Section 6 Cabling Diagram Index 151...

Page 159: ...ExpressCard 1000 Hardware Service Manual 152...

Page 160: ...Section 6 Cabling Diagram Index 153...

Page 161: ...ExpressCard 1000 Hardware Service Manual 154...

Page 162: ...Section 6 Cabling Diagram Index 155...

Page 163: ...ExpressCard 1000 Hardware Service Manual 156...

Page 164: ...Section 6 Cabling Diagram Index 157...

Page 165: ...ExpressCard 1000 Hardware Service Manual 158...

Page 166: ...Section 6 Cabling Diagram Index 159...

Page 167: ...ExpressCard 1000 Hardware Service Manual 160...

Page 168: ...Section 6 Cabling Diagram Index 161...

Page 169: ...ExpressCard 1000 Hardware Service Manual 162...

Page 170: ...Section 6 Cabling Diagram Index 163...

Page 171: ...ExpressCard 1000 Hardware Service Manual 164...

Page 172: ...Section 6 Cabling Diagram Index 165...

Page 173: ...ExpressCard 1000 Hardware Service Manual 166...

Page 174: ...Section 6 Cabling Diagram Index 167...

Page 175: ...ExpressCard 1000 Hardware Service Manual 168...

Page 176: ...Section 6 Cabling Diagram Index 169...

Page 177: ...ExpressCard 1000 Hardware Service Manual 170...

Page 178: ...Section 6 Cabling Diagram Index 171...

Page 179: ...ExpressCard 1000 Hardware Service Manual 172...

Page 180: ...Section 6 Cabling Diagram Index 173...

Page 181: ...ExpressCard 1000 Hardware Service Manual 174...

Page 182: ...Section 6 Cabling Diagram Index 175...

Page 183: ...ExpressCard 1000 Hardware Service Manual 176...

Page 184: ...Section 6 Cabling Diagram Index 177...

Page 185: ...ExpressCard 1000 Hardware Service Manual 178...

Page 186: ...Section 6 Cabling Diagram Index 179...

Page 187: ...ExpressCard 1000 Hardware Service Manual 180...

Page 188: ...Section 6 Cabling Diagram Index 181...

Page 189: ...ExpressCard 1000 Hardware Service Manual 182...

Page 190: ...Section 6 Cabling Diagram Index 183...

Page 191: ...ExpressCard 1000 Hardware Service Manual 184...

Page 194: ...Appendix A 187 Notes...