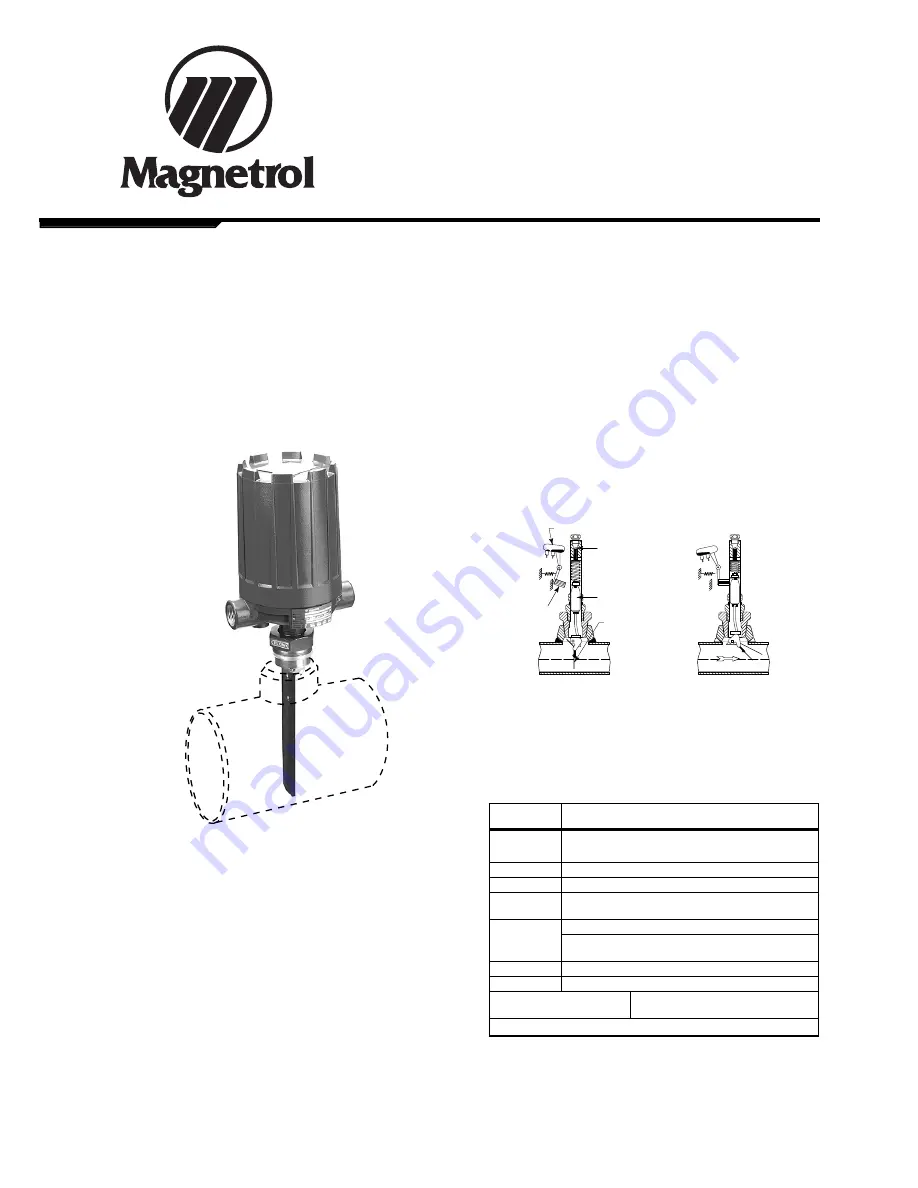

F10

Vane type

flow switches

®

INSTRUCTION MANUAL AND PARTS LIST

DESCRIPTION

The F10 is a vane type flow switch designed to be installed

in 2" through 30" horizontal pipeline by means of a threaded

or flanged connection.

OPERATING PRINCIPLE

The actuating vane is magnetically linked to a pivoted

electric (or pneumatic) switch, which is isolated from the

process by a non-magnetic barrier tube. As the actuating

vane moves with an increase in flow, it drives a magnetic

sleeve

①

into the field of a permanent magnet

②

located

outside the barrier tube

③

which trips the switch. As flow

decreases, the actuating vane returns to a vertical position,

allowing the magnet and switch assembly to return to the

“no Flow” position.

Switch mechanism

Adjusting screw

Magnetic sleeve

Actuating vane

Magnet

NO FLOW

POSITION

POSITION WITH

ACTUATING FLOW PRESENT

AGENCY APPROVALS

Agency

Approval

ATEX

II

2G EEx d

II

C T6, explosion proof

II

1G EEx ia

II

C T6, intrinsically safe

CEnElEC

EEx d

II

C T6, explosion proof

CCE

➀

R1 (1) 136/MI/433, explosion proof

FM

Class

I

, Div. 1, Groups C & D

Class

II

, Div. 1, Groups E, F & G, Type nEMA 7/9

FM/CSA

➁

non-Hazardous area

Explosion proof area –

Groups B, C, D, E, F & G Type nEMA 4X/7/9

SAA

➁

Explosion proof area

lRS

lloyds Register of Shipment (marine applications)

GOST/

Russian Authorisation Standards

GOSGORTECHnADZOR

➁

Other approvals are available, consult factory for more details

➀

For CCE approved units, use the ATEX explosion proof model

numbers.

➁

Consult factory for proper model numbers.