4.5.3

Cutterbar Spindles

Discs are factory installed to produce three crop-streams, but disc rotation patterns can be changed to suit

crop conditions.

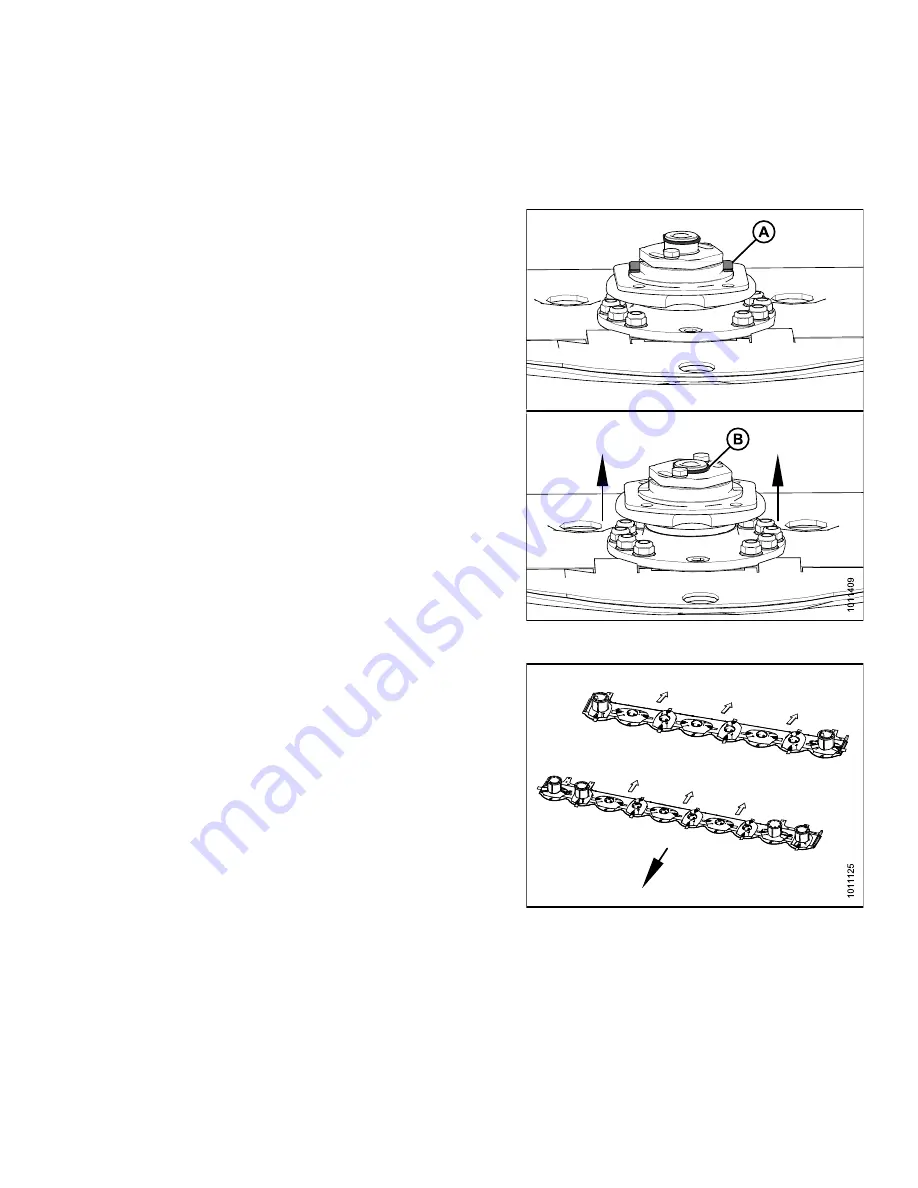

To prevent damage to the cutterbar and drive systems,

each disc is attached to a spindle containing a shear

pin (A). If the disc contacts a large object such as a stone

or stump, the pins will shear and the disc will stop rotating

and move upwards while remaining attached to the spindle

with a snap ring (B). Refer to

to replace shear pin.

IMPORTANT:

• Spindles that rotate counterclockwise have left-handed

threading and machined grooves on the spindle nut.

• Spindles

that

rotate

clockwise

have

right-handed threading.

Figure 4.44: Cutterbar Spindles

Reducing or increasing the number of crop streams will

produce the following results:

• Reducing the number of crop streams will result in

narrower windrows.

• Increasing the number of crop streams will result in

smoother, wider windrows.

NOTE:

Increasing the number of crop streams will

also increase the number of diverging disc

pairs which may negatively affect cut quality in

certain conditions.

Figure 4.45: 13- and 16-Foot Cutterbar

169820

143

Revision A