262391

114

Revision A

4.4.7

Maintaining Disc Blades

Each disc has two blades attached at opposite ends that are free to rotate horizontally on a specially designed

shoulder bolt.

1004001

A

Figure 4.63: Disc blades

Each blade (A) has two cutting edges and can be flipped over so

that the blade does not need replacing as often.

The blades are

NOT

repairable and must be replaced if severely

worn or damaged.

IMPORTANT:

Always use factory replacement parts.

NOTE:

Discs are equipped with 18° bevel-down blades; 11° bevel-down

blades are offered as a non-standard option. For more

information, refer to the header parts catalog.

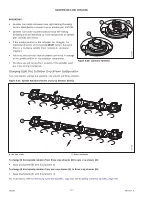

Inspecting Disc Blades

The blades on the rotary disc header

’

s discs should be inspected daily and flipped or replaced as needed.

DANGER

To prevent injury or death from the unexpected start-up or fall of a raised machine, always stop the engine and remove

the key from the ignition before leaving the operator

’

s seat or making adjustments to the machine. If the rotary disc

header is raised, always close the lock-out valves, and place blocks under the header. Never work on or beneath an

unsupported header.

DANGER

Ensure that all bystanders have cleared the area.

WARNING

Disc blades have two sharp cutting edges that can cause serious injury. Exercise caution and wear gloves when working

with, or near, blades.

WARNING

Damaged or loose disc blades or blade attachment hardware can be ejected during machine operation and may cause

personal injury or machine damage.

IMPORTANT:

Damaged blades cut poorly and may damage the cutterbar. Replace damaged blades immediately.