262391

111

Revision A

1011305

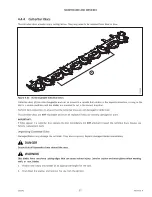

B

A

C

D

Figure 4.58: Cutterbar Disc and Cap

14. Place a pin (or equivalent) in front hole (D) of the rock

guard to prevent the disc from rotating while you are

tightening the bolts.

IMPORTANT:

The blades are oriented to cut in one direction or the other.

Therefore, swap the entire disc when swapping spindles.

15. Position disc (A) on the spindle, ensuring that it is

positioned at a 90° angle relative to the adjacent discs.

NOTE:

Turn disc (A) by hand to ensure that the disc blades do not

contact each other or adjacent discs.

16. Install cutter disc cap (B) and secure the assembly with four

M12 bolts and washers (C). Torque the bolts to 85 Nm

(63 lbf·ft).

WARNING

Ensure that the cutterbar is completely clear of foreign objects. Foreign objects can be ejected with considerable force

when the machine is started, which can result in serious injury or cause damage to the machine.

17. Remove the pin (or equivalent) from the front hole of the

rock guard.

18. Close the cutterbar doors. For instructions, refer to

3.4.2 Closing Cutterbar Doors, page 27

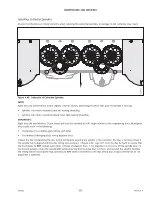

4.4.6

Reconfiguring Cutterbar Crop Stream

Discs are factory-installed to produce three crop streams; however, the disc rotation pattern can be changed by changing

the spindle and its disc to suit crop conditions. Each spindle and disc pair is designed to rotate in one direction, and must

be changed as a set when the crop flow is altered.

1011125

Figure 4.59: Cutterbars

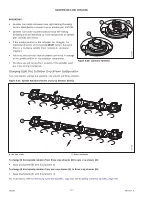

Reducing or increasing the number of crop streams will produce

the following results:

•

Reducing the number of crop streams will result in narrower

windrows.

•

Increasing the number of crop streams will result in

smoother, wider windrows.

NOTE:

Increasing the number of crop streams will also increase the

number of diverging disc pairs. This may negatively affect

the quality of the cutting.