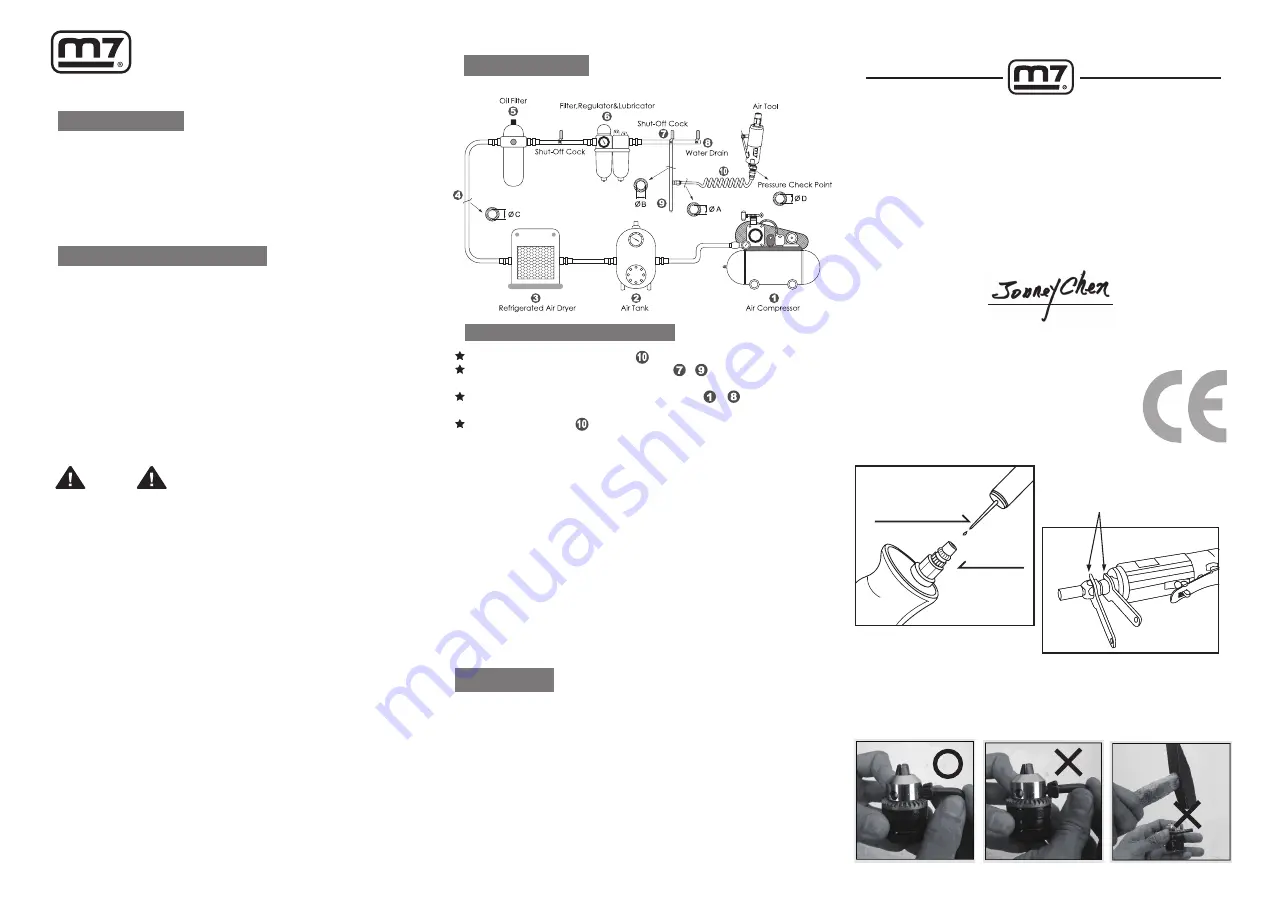

The diameter ΦA required for the inlet pipe is recommended on the specification table.

The diameter ΦB required for the branch pipe (from to ) should be 2 times as large as

ΦA. ΦB = 2 x ΦA

The diameter ΦC required for the primary air supply (from to ) should be 3 times as

large as ΦA. ΦC = 3 x ΦA

The length for the inlet pipe should be less than 15 feet (4.5m).

1.The maximum recommended air pressure during operation must not exceed

90 psi (6.3bar). Higher air pressure may create unsafe operating conditions for

the tool and the user.

2.The compressed air should be cooled and have a water filter installed at the

outlet end of the compressor. Even with a water filter installed, some water

may still condense in the piping or hose and will enter the tool mechanism

causing premature damage to the tool. Therefore, it is recommended to install

an air filter-lubricator device somewhere between the tool and the compressor.

3.Always use an air compressor of the proper capacity to operate each tool.

4.Clean the hose with a blast of compressed air before connecting the hose to

the air tool. This will prevent both moisture and dust inside the hose from

entering the tool and causing possible rust or malfunction.

1.Using these tools in any potentially explosive environment is strictly prohibited.

2.It is always recommended that these types of tools must be operated when

standing on a solid or firm location.

3.Always use these tools in a well ventilated area.

4.Slipping, stumbling and falling are the major causes of potential serious injury,

therefore, a clean and clutter free surface in the working area before operating

the tools is strongly recommended.

Read this manual carefully before installing, operating,

servicing or repairing.

Working environment:

Air supply and connection requirements:

Working environment:

Piping diameters and length requirement:

1. This tool should only be used as a hand operated tool. It is powered by compressed air and is

not insulated against electric shock.

2. This tool is specially designed for grinding sharp edges, burrs or surfaces on certain spots

or inner holes. Any application or use of this tool other than what it is designed for is strictly

prohibited.

3. High sound levels may cause hearing damage. Always wear hearing protection when operating

this tool.

4. Wearing eye/face protection can reduce the danger of high-speed materials being emitted from

the tool.

5. User must wear proper clothing. Loose clothing, long hair, stings, straps, belts and jewelry

should not be worn when operating this tool.

6. Working with certain materials can create dust and fumes, which may cause a potential

explosive environment and a hazard to the health. Therefore, wearing proper breathing

protection and taking preventive measures are recommended.

7. Always wear gloves to reduce the risk of cuts or burns.

8. Make sure that all the specifications of the shank stone to be used are compatible with this

tool.

9. Do not use cutting wheels on this tool.

10. Inspect the shank stone carefully before use. Use of chipped, cracked or otherwise defective

implements will create an unsafe condition.

11. Make sure that the allowed operating speed of the grinding shank stone is higher than this

tool.

12. Make certain that the minimum gripping length on the stem of shank stone should be 10mm

observed.

13. Make sure that the shank stone is correctly mounted and tightened before use. Then, run the

tool at no-load for 30 seconds in a safe location to check the function and rotating direction.

Stop immediately if there’s considerable vibration or any other defects.

14. Ensure that the work piece is properly supported or fixed before operating.

15. Ensure that there is no bystander in the vicinity of working area.

16. Make sure that the direction of the sparks generated from the grinding shank stone is properly

directed so as not to create a hazard.

17. Release the throttle lever to avoid danger if there is a failure of energy supply and when

connecting or disconnecting the air hose.

Warning:

18. To prevent an accidental start and cause a hazard, rest the idle grinder in a stable position.

19. Always turn off the air supply and disconnect the air hose before replacing grinding shank

stone or making adjustments on the tool.

20. Examine the shank stone thoroughly before re-use if this tool has been dropped.

21. Beware if the compressed air hose breaks unexpectedly, or is being connected or

disconnected improperly. This whipping action may cause injury.

22. Prolonged use will cause user fatigue. Periodic breaks are recommended for user safety.

23. It is recommended to stop operating the tool whenever the user experiences discomfort,

tingling or pain during use.

24. Make sure there is no gas or combustible material stored near the tool when servicing,

changing insert tools, or storage.

25. Avoid storing this tool where it is subject to high humidity.

1. Before connecting the air hose to this tool or after operating, apply 4 or 5 drops of pneumatic

oil into the air inlet and run it for several seconds, referring this operation to the attached

picture.

2. Maintain this tool regularly by performing the same oiling application every 3 to 4 hours of

operation.

3. Do not lubricate tools with flammable or volatile liquids. Use only the lubricant recommended

by Mighty-Seven or authorized dealers. Any other lubricant will lead to reduce performance

of the tool and permanent damage. Whenever any unauthorized lubricant is used by

accident, flush it immediately with recommended pneumatic oil.

4. Follow all the recycling laws of waste disposal once this tool is no longer usable.

Maintenance:

.

Original Language

Serial Number: Please refer to the tool

Air Die Grinders

Item No.: QA-681

6.3 bar (90. psi)

We declare under our own responsibility that the above machinery fulfils all the

relevant provisions of (MD) Machinery Directive 2006/42/EC and its

amendment and is manufactured and tested according to the following

standards:

EN ISO 11148-9 / EN ISO 15744 / EN ISO 28927-12

Jonney Chen

Declared by: QA Manager

Declared in: Taichung, Taiwan

Dated:201

8

/0

1

/01

Manufacturer:

Mighty Seven International Co., Ltd.

No. 70-25,Ching Qunag Rd., Wu-Jih Shiang,

Taichung Hsien, 41466 Taiwan

www.mighty-seven.com

Authorized contact, to compile the technical files :

King Tony France

3 Rue des imprimeurs ZI République Nord 1.

86000 POITIERS FRANCE

TEL

:

(+33) 5-49-30-30-90

:

Signature

CE DECLARATION OF CONFORMITY

Shank stone replacing:

Use the supplied spanners to replace.

Note: Turn counterclockwise to open

and replace.

Pneumatic oil

Air inlet

Regular maintenance