IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-70

March 2020

Page 243

IO-390-D Series Engine Maintenance Manual

72-70 - ELECTRICAL SYSTEM MAINTENANCE

1.

Wiring Inspection

A.

Examine the aircraft electrical wiring for correct routing, security, clamping, deterioration,

and chafing in accordance with the aircraft manufacturer’s instructions. If wires are worn,

chafed, or frayed take corrective action in accordance with the aircraft manufacturer’s

instruction.

B.

Make sure the wiring connections are tight. Tighten any loose wiring connections.

2.

Alternator Belt Inspection

NOTICE:

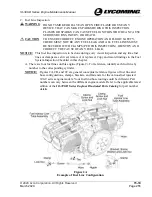

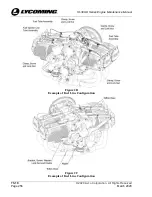

There either can be a single alternator or dual (twin) alternators.

A.

Examine the alternator belt(s) (Figure 1) for any cracks, damage, or wear.

B.

Complete the “Alternator Belt Tension Check/Adjustment” procedure in this chapter.

C.

Replace a worn, cracked or damaged alternator belt.

Figure 1

Alternator and Alternator Belt

3.

Alternator Belt Tension Check/Adjustment

CAUTION

IF THE ALTERNATOR BELT TENSION IS NOT SET CORRECTLY, THE

ALTERNATOR BELT CAN SLIP, WEAR PREMATURELY, AND FAIL.

A.

When to complete an alternator belt tension check.

(1)

Immediately after the alternator belt is replaced and then after 25 hours of operation after

alternator belt installation.

(2)

During each 100-hour service inspection thereafter.

B.

Use any of the following three methods to complete an alternator belt tension check:

•

Torque Method

•

Deflection Method

•

Belt Tension Dial Gage Method

NOTICE:

Refer to the latest revision of Service instruction SI-1129 for any new details on

alternator belt tension check.