IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 129

IO-390-D Series Engine Maintenance Manual

72-20 - RECIPROCATING ENGINE – CRANKCASE MAINTENANCE

1.

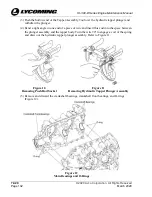

Crankcase Inspection Before Disassembly

A.

The crankcase inspection is done to:

•

Identify any oil leaks, cracks, and mechanical damage on the crankcase

•

Make sure that hardware fasteners are torqued correctly

WARNING

IF A DAMAGED OR CRACKED CRANKCASE IS NOT REPLACED, OIL

CAN LEAK OUT OF THE CRANKCASE AND CAUSE ENGINE

DAMAGE. DO NOT TRY TO WELD OR REPAIR A CRACKED

CRANKCASE. REPLACE THE CRANKCASE.

B.

Examine the exterior surface of the crankcase per the Visual Inspection Checklist for IO-390-

D Series Engines. Replace a damaged crankcase or a crankcase with one or more cracks.

C.

Complete a check of the torque on the crankcase hardware fasteners per the Standard Torque

Tables in the latest revision of the

Service Table of Limits - SSP-1776

.

D.

Examine the crankcase breather for cracks, dents, and damage. If cracks, dents or damage are

found, remove the engine as per Chapter 72-00 and send to Lycoming Engines.

E.

Examine the ends of the breather tube for scoring and out of roundness. If scoring or out-of-

roundness is found, replace the breather tube,

NOTICE:

In the next step, do not use a torque tool during the check for loose crankcase thru-

bolts.

F.

Manually turn by hand each crankcase thru-bolt as a check for loose bolts. If the bolt can be

manually turned, remove the bolt and examine the bolt for stripped threads. If the bolt threads

are intact, install and torque the bolt in accordance with the Standard Torque Tables in the

latest revision of the

Service Table of Limits - SSP-1776.

G.

Replace any crankcase hardware fastener that is distorted or has stripped threads. Torque all

hardware fasteners per the Standard Torque Tables in the latest revision of the

Service Table

of Limits - SSP-1776

and in the correct sequence identified in this chapter.

2.

Connecting Rod Removal

CAUTION

DO NOT RE-USE THE CONNECTING ROD BEARINGS, BOLTS, AND NUTS.

NOTICE:

If the two nuts in the connecting rod cap cannot easily be removed, use a soft (plastic

head) mallet and gently tap on the end of the two bolts to remove the nuts and the bolts.

(1)

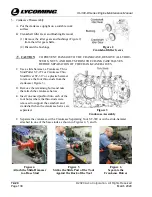

Remove and discard the two nuts (Figure

1) and the two bolts that attach the

connecting rod cap to the connecting rod.

(2)

Remove the connecting rod cap and

connecting rod; keep them together, apply

a label to identify the throw position of the

connecting rod for reference on assembly.

(3)

Remove and discard the two connecting

rod bearings.

Figure 1

Connecting Rod Parts